How to fix a computer mouse. Disassembling and repairing a computer mouse Disassembled mouse

Reading time: 3 min.

A computer mouse is a key mechanism for comfortable work with a computer. It can be used to control PC menu functions. Since the mouse is used actively, it also breaks often and unexpectedly. Its device does not have a complex design. The mouse can be completely disassembled and repaired with your own hands, having a minimum set of tools and knowledge. To find out how to disassemble a mouse without bolts without consequences, you should study the features of its fastenings.

Features of fastenings

The mouse consists of two parts: a body, a wheel and internal parts. The top housing is divided into two main buttons. The upper and lower parts are bolted together. Usually manufacturers hide them under bearings or stickers. Most mice have four mounting screws located under the feet on the bottom of the case. These feet allow you to glide easily across the mat. They peel off and stick back.

Often you come across devices with one bolt on one side of the case. The second side is fixed with latches. If the screws are not visible at all, then there are latches around the entire perimeter. To disassemble the mouse, you need to press lightly on them.

Inside there is a printed circuit board, most often not secured with screws. It is mounted with holes on plastic rods protruding from the body. On some models, the board is secured with one or more bolts.

Device repair

A computer mouse can fail for various reasons. The most common:

- clogging;

- oxidation of metal contacts;

- damage to the wheel axle;

- wire damage.

Almost all problems can be fixed at home. To do this you need to follow some steps:

- Prepare the necessary tools.

- Disconnect the mouse from the computer.

- Disassemble the case by pressing on the latches or unscrewing the screws.

- Open the case halves using a screwdriver with a rubber or plastic bat that will not leave scratches on the plastic of the device.

- You need to disconnect parts of the mouse carefully, without sudden movements, so as not to break the internal wires.

- There is a chip inside. It needs to be disconnected and removed from the groove, as well as other buttons if we are talking about a gaming mouse.

- After repair, assembly must be carried out in the reverse order.

Repair may consist of the following manipulations:

- The broken wire should be soldered.

- A broken wheel axle can be made from a regular paper clip.

- Clogged areas should be cleaned with a special wipe or clean soft cloth.

After all the necessary activities have been completed, you can begin assembly. First, install the wheel in place, screw the board and return the additional buttons to their place. Then you need to carefully connect the halves of the housing and screw in the bolts, or press the parts together at the locations of the latches until a characteristic click is heard. The mouse is assembled - you can check its operation.

Preparing tools

To disassemble and repair the mouse, you will need a minimum set of tools:

- Screwdriver Set;

- scissors;

- soldering iron

You should use medical gloves to avoid leaving greasy fingerprints on the board or internal contacts. To remove blockages you need a special napkin. In extreme cases, a piece of soft, clean cloth will do. Do not use water with detergents or solvents for cleaning. You need to take regular alcohol. You can moisten a cotton pad with it and wipe the board, wheel, and case from the inside. The optical sensor is cleaned with a toothpick and cotton wool, also soaked in alcohol.

Wireless mouse repair

Wireless devices often fail due to dead batteries. If the mouse stops responding to movement or responds poorly to manipulation, then most likely the batteries should be replaced. Most wireless models have an operating indicator light, so the health of the batteries can be checked by the indicator glowing red.

Discharged batteries are easily removed. On the “sole” of the mouse you need to open the compartment cover and remove the batteries. It also wouldn’t hurt to check the contacts in the device and on the battery terminals. Over time they oxidize. The resulting deposits are removed with a rag soaked in alcohol. It is not recommended to use sandpaper - you can remove the protective galvanic film.

Computer mouse - small, but very important device for PC users. It experiences heavy mechanical load during active use. Over time, this leads to breakdowns, most of which can be fixed at home. A few screwdrivers, a soft cloth, ammonia and gloves, as well as a little patience and a serious approach to repairs will save money and time.

If your computer mouse is broken, do not rush to buy a new one. It is quite possible that you will be able to repair the breakdown yourself and the device will serve you for many more years.

Mouse sensor is acting up

Often there is also a situation when we cannot accurately move the cursor to a certain point. It constantly trembles and moves on its own. This situation clearly indicates that the optical group of the mouse is clogged.

Clogging is most often external. Dust or hair gets into the compartment where the diode light is reflected from the table. To get rid of such a blockage, you don’t even need to disassemble the mouse. Just turn it over and blow it out. As a last resort, use a small brush to remove stuck debris.

If even after such manipulations the mouse cursor trembles, then, most likely, either the sensor is clogged inside or has completely failed. In any case, you can try to disassemble the mouse and clean the sensor using a toothpick with a cotton swab soaked in alcohol wrapped around it:

Before cleaning the sensor with a cotton swab, you can also try blowing it to remove any fine dust that may stick after it gets wet. After this, carefully, without pressing, insert the toothpick with rotational movements into the sensor hole. After making a couple of turns and without stopping rotating, we take out the toothpick, wait for the alcohol to dry and try to connect the mouse.

If, after all attempts at cleaning, the sensor does not work normally, then if you have another mouse, a soldering iron and straight hands, you can unsolder the non-working microcircuit and replace it with a sensor from another mouse. However, this already requires a certain skill, so not everyone will be able to pull it off...

Mouse wheel scrolls

It happens that the mouse works fine, but when we try to use its wheel, the page we are scrolling begins to jump up and down, or does not want to scroll at all. Alas, failure of the mouse wheel is a fairly common failure and it was this that prompted me to write this article.

First you need to carefully consider how evenly the wheel rotates in the groove. The groove itself and the wheel axle have a hexagonal cross-section, but sometimes one or more sides of this hexagon can become deformed, resulting in the axle slipping in the problem area.

If you have just such a problem, then it can be solved by sealing the edge of the wheel axle with adhesive tape or electrical tape in small quantities. If everything is normal with the movement of the wheel, then the breakdown has occurred inside the encoder (scroll sensor). It may have become loose from prolonged use and should be tightened a little:

To do this, take small pliers and press them one by one on the four metal brackets that secure the encoder to the plastic parts of the scroll mechanism. The main thing here is not to overdo it and not break the fragile plastic, but at the same time press harder. Try connecting the mouse and checking whether the negative effect when scrolling decreases after each click.

Alas, in my case it was not possible to completely get rid of jerks. Yes, the frequency and spread of page jumps have decreased, but the jumps themselves have not completely disappeared. Then I decided to approach the issue of sealing radically and in a truly Russian way :) I cut out a piece of thin but dense polyethylene from an old battery pack and stuck it inside the mechanism:

What’s most interesting is that this manipulation helped! All I have to do is cut off the excess length of the strip and assemble the mouse :)

Mouse buttons don't work

The last, and most annoying, breakdown is the non-working button. Whether it's left, right or the one under the wheel doesn't matter - they're all usually the same. The important thing is that a non-working button cannot be repaired in any way. You can only replace its microswitch by removing the non-working one with a soldering iron and replacing it with a new one or one borrowed from another mouse.

The microswitch has three “legs”, the first of which is a regular clamp, and the other two are contacts that need to be soldered. There is no need to solder the fastener. It only serves as a “fool proof” to prevent you from inserting the microswitch in the wrong direction by mistake.

Sometimes the button still works, but it doesn’t work every time you press it. Such a symptom may indicate that the edge of the button pusher, which presses the microswitch, has worn away due to frequent use.

We disassemble the mouse and carefully examine the problematic button and its pusher. If we see a small dent, then that may be the problem. It is enough to fill the dented area with a drop of epoxy resin or melted plastic.

The last problem you may encounter is that the mouse button double-clicks when you click on it. This issue can be solved by re-soldering the microswitch or... programmatically! In any case, before you take up the soldering iron, check that the mouse settings are correct in the Windows Control Panel:

By default, the double-click speed slider should be in the center, and the sticky mouse buttons option should be disabled. Try setting these parameters and check if the problem is resolved. If not, another radical programmatic method Double-click "cure" - remove the mouse driver. How to properly remove a driver is written.

conclusions

Mice are one of the most actively used computer devices. Therefore, it is not surprising that they often fail. However, due to the simplicity of their design, in most cases anyone can fix a mouse!

To do this, you don’t need to know how to solder or understand electronics. The main thing is to clearly diagnose the cause of the breakdown. Here, as in medicine, a correct diagnosis is the path to successful repair.

I hope our article will allow you to determine what exactly is broken in your mouse, and therefore, to fix the problem. Good luck with your renovation!

P.S. Permission granted to freely copy and quote. this article provided that an open active link to the source is indicated and the authorship of Ruslan Tertyshny is preserved.

Computer mice manufactured on this moment, have good reliability. They can work without repair for several years. However, over time they refuse to work. You have to buy a new mouse or repair the old one yourself. Since the workshop charges quite a lot of money for this.

Often, mouse failure is caused by fraying of the wire at the point where it exits the case or poor contact that occurs in the mouse buttons. Often, this is the left key, since it is the one that is used most often. To repair the mouse, you will have to disassemble it.

How to disassemble a computer mouse

The first step is to unscrew the mounting screws, they are located on the bottom side. There may be several of them, but almost always it is one screw. This mouse model is held together by one screw.

If you cannot find the screw, it means it is covered with a label. Press down on the label; if it bends, the screw is located underneath it. To disassemble this mouse, I had to partially peel off the sticker.

The TECH X-701 model is held together with two screws. One of them is under the label. When an attempt was made to peel off the label, it began to tear. I had to feel for the screw and unscrew it without removing the sticker. In the photo the location is shown with a blue circle.

If there are no screws under the sticker, then they are hidden behind the thrust bearings. They should be peeled off by prying them off with a knife. After the mouse is repaired, the thrust bearings should be returned to their place. If this is not done, the mouse will not glide well on the mousepad.

After all the steps, remove the cover of the mouse on which the buttons are located.

Most often, the printed circuit board is not fixed in the mouse body. It simply slides onto plastic rods. If, when you try to remove the board, it does not budge, then you should look for screws. This mouse model uses a screw to secure two elements at once: the body and the board.

The board is removed by prying it from below, and the wheel axle should be removed from the latches.

Carefully inspect the mouse before disassembling, remember the location of the parts. Pay attention to the wheel ratchet spring, if there is one. It is similar to a clothespin spring, only smaller in size. If you don't like the rotation of the wheel, bend the ends of this spring. Then the wheel will rotate more smoothly due to reduced pressure.

Make sure that when disassembling, your fingers do not touch the optical prism and optical elements. If this happens, do not use any detergents. There are special wipes for removing grease stains. If they are not available, wipe the optical elements with a dry cloth.

How to repair a frayed mouse wire

If, while working at the computer, you begin to notice the cursor moving without permission or freezing, this may be due to a broken wire. This is easy to check. Press the wire against the mouse body and make a movement. If the cursor moves along a given axis, it's all about the explorer.

If damage is noticed at the point where the wire exits the mouse, it is the cause of the mouse failure. Here is one example of a breakdown. The photo clearly shows that the outer sheath of the wire is damaged. Some conductors simply frayed. This mouse is repairable.

If you have the skill to work with a soldering iron, repairing the mouse will not be difficult. It is enough to remove the damaged section of the wire, prepare new solder ends and solder them. All that remains is to connect the wire to the printed circuit board.

How to repair a frayed mouse wire by soldering

There are two types of wire connecting the mouse to the connector: tinsel and regular stranded. Tinsel is a more elastic and soft wire. It is resistant to bending that occurs when using a mouse. Accordingly, it lasts longer.

The wire is laid along the mouse body and connected to printed circuit board. There are two options for attaching this wire. Using a detachable connection and by pressing into the board block. The photo shows a block that has been desoldered from the printed circuit board. The conductors are pressed into it.

In order not to forget the location of the wires on the board, it is better to take a photo. Then the connector or block is desoldered from the board. In this case, it is better not to disconnect the wires. Wire color scheme may vary. Since there is no single standard, manufacturers select wires at their discretion.

I repaired different mice and in all of them the wires had a different color. Most likely, this is due to the fact that the mouse repair field is warranty period not provided. After the old wires have been soldered from the board, it is necessary to remove the remaining solder. To do this, heat it up with a soldering iron and, using a thin match or toothpick, squeeze the solder out of the hole. Places for new conductors have been prepared.

Before you start soldering, you need to prepare the wires. Cut off the bad piece of wire to a length of 15-20 mm. We remove the insulation and tin the ends with solder. To ensure that the tinned edges have a round shape, the wires should be laid on a wooden stand and tinned by rotating. If this is not done, the wires will not fit into the holes on the printed circuit board. Then we insert them into the board and solder them according to the color marking.

Tinsel conductors are not amenable to tinning with rosin flux. This is because they are insulated with varnish. Acid cannot be used in this case; after some time it will destroy the conductor. It is best to take an aspirin tablet.

There are cases when the printed circuit board has a small diameter of holes for the wires. In this case, the conductors can be soldered to the contact pads. There will be no physical stress on the wire, so this type of connection will be quite rigid.

That's it, you can return the printed circuit board to its place. We lay the wire and secure the board with screws. Make sure that the wire does not touch moving parts, is not placed under button pushers, or is crushed by the housing. Before closing the case with the lid, make sure that excess dirt and hairs are removed. You can use the mouse.

How to repair a frayed mouse wire by twisting it

There is no safer way to repair a mouse wire than soldering. However, not everyone has a soldering iron and not everyone can solder. If you do not have a soldering iron, you can repair the wires by twisting them. To do this, you should disassemble the mouse and cut off the section of wire with the defect.

Using a sharp knife blade, cut the outer insulation on both ends of the wire. About 5-6 cm.

The length of the conductor must be selected in such a way that when twisting the wire, the connection points are shifted by 5-8 mm relative to each other. The ends of the insulation must be stripped.

Conductors of the same color are twisted together.

The twists must be bent along the wires. Then tuck them into the previously cut insulation. Please make sure that the twists do not touch each other.

A second piece of insulation must be applied to the resulting connection.

This will increase mechanical protection and protection against contact with parts on the mouse board.

All that remains is to insert the wire connector into the connector on the printed circuit board. Then carefully lay the wire along the mouse body.

The mouse is covered with the top cover, the screws are screwed in. You can use the mouse for its intended purpose. Wires connected in this way will last another period. It happens that the mouse connector is located far away.

And the wire is not long enough to connect the mouse. Then, according to the same scheme, we increase the missing piece of wire. You can take it from an old mouse. Wires may have different color markings, since there is no single standard. Therefore, before I twist the wires, ring them. To increase the life of the mouse, make sure that the wires at the point where they exit the housing are not bent.

If the mouse wheel starts to work poorly

Sometimes, when you rotate the wheel on your mouse, you notice that the page does not turn at all or it happens in jerks. The reason for this may be dust and hair getting between the photodetector of the optocoupler and the photosensor of the wheel. So how does dirt get into your mouse? Through the gaps between the body and the wheel. Since there is a lubricant inside that improves sliding, foreign objects stick to it.

After removing hair and dust, the wheel works like new.

How to replace a microswitch

If you find that nothing happens when you press the mouse buttons, you should start repairing. The reason for this may be the failure of the microswitch or wear of the button formed at the point of contact with the pusher.

To find out the reason, you need to disassemble the mouse and inspect it. If there is a slight depression, about 1 mm, this may be the reason. Check the button pushers by pressing them. There should be a loud, clear click. If this is not the case, it is most likely the switch itself.

This is checked as follows: the disassembled mouse is connected to the computer, and by pressing the pushers, it is checked. If everything works, you need to fuse the missing piece of plastic onto the button, or pour a drop of epoxy resin. If the failure lies in the microswitch, it will have to be replaced.

It's easier to replace the entire switch than to bother with re-soldering wires. Most mice use a standard microswitch. It works on the following principle. 3 brass plates having a complex shape are pressed into the body, made of plastic. Their ends have pins that are used for soldering into the board.

The plate located on the left in the photo is the middle point of the switch. A plate having a “U”-shaped hole is attached to it using the expansion method. This plate is attached with the left side to the protrusion of the left plate on the left side. The right side is curved in an arc; it hooks onto a protrusion located on the right side of the left contact plate.

The flat thin plate is made in such a way that its right end is pushed upward. Due to this, contact is created with the thick right plate, bent into the shape of the letter “L”. When you press a key, the pusher transmits force to a thin plate. Consequently, it descends, moving away from the upper contact, and touches the lower one. The output of this contact is located in the middle of the button.

After you release the button, the thin plate returns to its initial position, due to which the extreme contacts of the switch are connected. It turns out that when the button is pressed, the contacts are connected to each other. This happens to the middle and left contacts. When the button is released, the outermost contacts are connected.

Since metal tends to accumulate fatigue, the spring becomes deformed and loses its properties. This is why the button refuses to work. Maybe the microswitch can be repaired.

Disassemble, remove the spring and straighten it. But I have never had to repair a switch this way. If you have an old ballpoint mouse, disassemble it and unsolder the microswitch.

It is better to solder the one located under the wheel. It is used the least often and is often in good working order. If the wheel is missing, take the right button switch. Just pay attention to how it is installed. The pins on the switch are located symmetrically to each other, it’s easy to make a mistake.

If the old mouse is missing, swap the switches. In place of the left button, install the switch from the wheel and vice versa. If the situation is extremely hopeless, there is nothing left to do but repair the microswitch.

All photos are clickable, click to enlarge

How to disassemble wireless mouse JET.A Comfort (OM-U54G) video guide I searched in vain on YouTube, I had to do it myself. But first, a few words about the mouse itself.

I bought this mouse about a year ago, the seller (DNS in Cheyabinsk, on Salyutnaya) recommended it as “almost gaming.” This prefix “almost” should have confused me right away... I needed a mouse for work, well, sometimes to play Dota, no frills, but not completely junk.

I looked at the characteristics - it seems to be what I need. It fits normally in the average man's hand for 800 rubles, which is not an option. Damn, I bought it...

We must pay tribute - the mouse worked for six months, the batteries last for 3-4 months. No complaints before the breakdown. But the quality of the components makes itself felt.

It has been noticed that DNS often sells elegant Chinese junk, they do not have merchandisers or a quality service, and there is no one to monitor what ends up on the counter.

So trouble happened with this mouse after 5-6 months, the right button died. I just fell in love. It so happened that at that time there was no time for nonsense (an urgent order), I went and bought a normal mouse, and threw this one in a box, until better times.

While sorting out the junk, I took out this mouse and decided to repair it, the big deal is the button. Usually in such cases I look for a parsing manual on YouTube, but this time I was out of luck. Have not found.  From personal experience I know that the body of a modern mouse usually has a screwless assembly - everything is held on by several latches.

From personal experience I know that the body of a modern mouse usually has a screwless assembly - everything is held on by several latches.  To disassemble the JET.A Comfort wireless mouse, you need to unscrew a couple of screws. The screws are hidden under the “rear legs” - you need to carefully peel off the Teflon stickers and then unscrew the screws.

To disassemble the JET.A Comfort wireless mouse, you need to unscrew a couple of screws. The screws are hidden under the “rear legs” - you need to carefully peel off the Teflon stickers and then unscrew the screws.

The photo clearly shows their location. The front part of the mouse body has standard latches.

broken button from my mouse

Further disassembly of the mouse, I think, will not cause any difficulties, everything is trivial. I would like to draw your attention to the buttons; this model uses typical D2FC-F-7N buttons - manufactured by OMRON. As you know, these microswitches come in different qualities; fake ones usually do not have the “Made in China” inscription.

On AliExpress they cost 160 rubles for 10 pieces.

Dear visitors!!!

Our modern life cannot be imagined without a computer; we communicate with our friends and relatives using the Internet. When we start working on a computer, sometimes we have to fix minor problems, namely:

- clogged laptop or computer fan,

- clogging computer mouse,

— with the help of which it becomes impossible to control the screen (laptop, computer). The topic contains personal photographs regarding a malfunctioning computer mouse, which is what I want to introduce you to.

Computer mouse repair

To make a computer mouse that stops working after a certain time, the problem here may be hidden in the simplest reason - contamination.

Clogging of this accessory occurs as a result of its use. When working at a computer, we often have to move the computer mouse and gradually it becomes clogged with dust, hair and other small particles. Of course, to fix it computer mouse, it needs to be disassembled.

How to disassemble a computer mouse

We unscrew the bolts (photo 1), carefully follow the sequence of disassembling the computer mouse.

We do not carry out any diagnostics on the circuit for electronic elements (diagnostics are carried out as a last resort). In two photographs (photo 2), in an enlarged plan, you can see a wheel with an axle, transmitting the signal of its rotation to the circuit. In the right photo, at the two ends of the wheel axis you can see small fragments of hair, lint and dust. Using a cotton swab, carefully remove small fragments of lint and dust; if some debris is difficult to remove, use tweezers.

After the regulations for removing dust and small fragments have been carried out, the computer mouse is assembled in the reverse order.

Contact cleaner

It would be a good idea to wipe the contacts of the connector connected to the socket of a computer or laptop with the same cotton swab. In addition to the connector, you also need to clean the socket contacts. For cleaning contacts (connector and socket), It is advisable to lightly moisten a cotton swab with alcohol. This regulation must be carried out carefully so as not to disrupt the electronic elements of the circuit itself. If you find a cable break in any area (between the connector and the mouse itself), soldering is used. Such a cable may consist of five wires. In my practice, the malfunction of the computer mouse was precisely the reason that I described. After fixing the malfunction of the computer mouse, I was satisfied with my work, the computer mouse became controllable again.

That's all for now. Follow the section.

Order 343 mail. Order by Russian post. Consequences of failure to appear in court when summoned

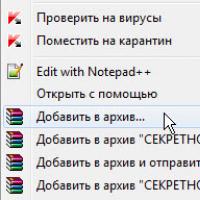

Order 343 mail. Order by Russian post. Consequences of failure to appear in court when summoned How to put a password on a folder on a Windows computer without and with programs

How to put a password on a folder on a Windows computer without and with programs Pluton – Free Bootstrap HTML5 One Page Template

Pluton – Free Bootstrap HTML5 One Page Template History of ZX Spectrum: Myths and reality New Spectrum

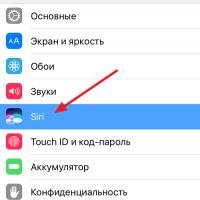

History of ZX Spectrum: Myths and reality New Spectrum Voice assistant Siri from Apple Siri functions on iPhone 6s

Voice assistant Siri from Apple Siri functions on iPhone 6s How to roll back to a previous version of iOS?

How to roll back to a previous version of iOS? Unlock iPad in four days

Unlock iPad in four days