The volume control does not work. Encoder. Encoder tape Cleaning the canon encoder tape and disk

Quite often, when inkjet printing, you can observe a horizontal shift of part of the image, appearing at regular intervals on the sheet. Many watching this problem, start aligning the print head, but this often does not help. So what is the cause of the defect? The fact is that almost every printing device (with the exception of some devices ten years ago) has a positioning tape - the so-called “encoder” (or encoder tape). It is designed so that the device always “knows” where this moment the printer carriage is located.

The principle of operation is that on the positioning tape on a short distance stripes are applied from each other. And on the printer carriage there is an optocoupler (a sensor that “sees” these strips). Thus, if the positioning tape is stained with ink or grease in any place, the carriage will “skip” this area, and a horizontal shift will occur when printing. It is clear that in this case the positioning tape must be cleaned. To do this, you need to open the printer cover and disconnect the power cord (so that you can move the printer carriage by hand). Find a positioning tape - a translucent tape with transverse marks, usually located above the guide along which the carriage moves.

The tape must be wiped without any effort or holding it with your hand, since it very easily comes off its fastenings, and in order to put it in place, you will most likely have to disassemble the device. For wiping, you usually use any swab (toilet paper, lint-free cloth, etc.) and alcohol (Mr. Muscle, cartridge cleaning fluid, etc.).

Cleaning the encoder tape with alcohol will only help if the tape is simply dirty and does not have strong mechanical damage, to which the optocoupler responds. Otherwise, you can try turning the tape backwards. In the worst case scenario, the tape will have to be replaced.

To be fair, it is worth noting that encoder tapes, as a rule, are installed on printers where the carriage moves due to the motor direct current(two wires). Stepper motors, in general, do not have this problem - they are more energy-intensive, and are more susceptible to incorrect positioning when the weight of the print head changes - in particular, light or very heavy CISS or a change in the coefficient of friction of the carriage when sliding along the guide lead to failures. Other problems are also possible, such as failure of output transistors, short-circuiting of motor windings, and the like.

It should be noted that this malfunction can manifest itself not only as horizontal tears or displacement during printing. Symptoms of this problem include a printer message about a carriage positioning error (Canon), a message about foreign objects inside the device (Epson), and even spontaneous paper grabbing with a subsequent message about a jam (Canon).

It is also worth paying attention to the encoder disk, which is located on the far left side of the device (Canon) - this is a disk that communicates through gears with the engine. On this disk There are also marks (marks) along which the sensor is oriented and determines the longitudinal position of the sheet. If this disk is dirty, then the following problem may appear: the sheet of paper will have tears, i.e., transverse stripes may appear on the sheet - the paper pulling mechanism, guided by this disk, pulls the sheet, and if the disk is dirty, then the sheet will pass in jerks.

An encoder is a device that converts linear or angular movement into a sequence of signals that allows you to determine the amount of movement.

The encoder strip in the printer is a navigation system. Without a raster tape, the printer will not be able to understand where the print carriage is located at the moment. And without this, it is impossible to understand at what point you need to start typing and where to finish. The raster strip is most often made on films using the photolithographic method. It is a thin transparent polymer film with black opaque stripes applied to it. If you look at the raster strip under a magnifying glass, you can clearly see these stripes.

The encoder strip is monitored by a raster sensor. It is located on the carriage and sends a signal at what point in time printing should begin and at what point to end. When setting up the printer, it is unacceptable to touch the encoder sensor to the encoder tape. In this case, data from the tape will not be read correctly, positioning errors and discrepancies in the printed image may occur. You should also avoid getting solvents or ink on the inside of the encoder sensor. This can lead to fogging of the lenses and damage the raster sensor. The encoder sensor consists of an infrared emitter on one side, and a photodetector on the other side. The operating principle of the raster sensor is as follows. Passing over the dark and transparent stripes on the raster tape, the sensor sends a signal to the printer control board, which determines the position of the carriage relative to the starting position. There are frequent cases when, due to poorly tensioned raster tape, the image splits or shifts with each pass. If you suspect that the encoder tape has worn out, you can first try turning the encoder tape back to front or upside down. In 50% of cases, this action helps solve the problem associated with the encoder tape.

To clean the ribbon, the printer must be turned off.

On older printer models, the encoder tape is not protected in any way and is visible without special problems, on new ones it is covered with a protective metal casing. If cleaning is necessary, you need to carefully, but with force, pull the casing up and towards you. Then it will jump out of the grooves. Be careful not to damage the tape.

After cleaning, the tape must be inserted into special grooves. The tape must be perpendicular to the rail. If not, it means it didn’t fit into the grooves. Snap the cover back in several places. After latching, drive it along the rail. If it moves relatively freely, it means it is latched. Then run the carriage with your hands along the rail to check for cling.

Cleaning the tape should be done using a soft material that will not deteriorate the condition of the encoder. For example, a lint-free napkin. When cleaning, do not press too hard on the tape, as this may erase the marks on the surface of the tape, which are important for proper movement of the carriage. You can clean the sensor carefully with cotton swabs.

Quite often when printing, you can observe a horizontal shift of part of the image appearing at regular intervals on the sheet. Many people observing this problem begin to align the print head, but this often does not help. So what is the cause of the defect? The fact is that almost every printing device (with the exception of some devices ten years ago) has positioning tape, so-called, "encoder"(or encoder tape). It is designed to ensure that the device always “knows” where the printer carriage is currently located.

The principle of operation is that stripes are applied on the positioning tape at a short distance from each other. And on the printer carriage there is an optocoupler (a sensor that “sees” the strip data). Thus, if the positioning tape is stained with ink or grease in any place, the carriage will “overshoot” this area and a horizontal shift will occur when printing. It is clear that in this case the positioning tape must be cleaned. To do this, you need to open the printer cover and disconnect the power cord (so that you can move the printer carriage by hand). Find a positioning tape - a translucent tape with transverse marks, usually located above the guide along which the carriage moves.

The tape must be wiped without exerting force or holding it with your hand, since it very easily comes off its fastenings and in order to put it in place, you will most likely have to disassemble the device. For wiping, you usually use any swab (toilet paper, lint-free cloth, etc.) and alcohol (Mr. Muscle, cartridge cleaning fluid, etc.).

It should be noted that this malfunction can manifest itself not only as horizontal tears or displacement during printing. Symptoms of this problem include a printer message about a carriage positioning error (Canon), a message about foreign objects inside the device (Epson), and even spontaneous paper grabbing followed by a jam message (Canon).

It is also worth paying attention to encoder disk, which is located on the far left side of the device (Canon) is a disk communicating through gears (gears) with the engine. This disk also has marks (marks) along which the sensor is oriented and determines the longitudinal position of the sheet. If this disk is dirty, then the following problem may appear: the sheet of paper will have tears, i.e. Transverse stripes may appear on the sheet - the paper feeding mechanism, guided by this disk, pulls the sheet, and if the disk is dirty, the sheet will pass through as if in jerks.

Cleaning the encoder tape with alcohol will only work if the tape is simply dirty and does not have severe mechanical damage to which the optocoupler reacts. Otherwise, you can try turning the tape backwards. In the worst case scenario, the tape will have to be replaced.

To be fair, it is worth noting that encoder tapes, as a rule, are installed on printers where the carriage moves due to a DC motor (two wires); stepper motors generally do not have this problem. Stepper ones are more energy-intensive and are more susceptible to incorrect positioning when the weight of the print head changes, in particular light or very heavy CISS, or when the friction coefficient of the carriage changes when sliding along the guide. Other problems are possible there, such as failure of output transistors, short-circuiting of motor windings.

For the time being, there is no mention of any carriage failure on our inkjet printers I didn't think so. I calmly typed until the problem literally “crept up” from behind. Another photo suddenly came out of the printer cloudy and not sharp. I checked the photo on the monitor - excellent quality. It is clear that the problem is with the printer. I did a nozzle test - everything is fine. It appears that the print head calibration has gone wrong. Let's try to calibrate. I go to the Start menu - Devices and Printers - Select your printer - Printing settings - Tools - Print head calibration. And then I see that during calibration, something unimaginable began to happen to the printer - the carriage began to literally hit the side wall of the printer. The “head” has lost its bearings.

On the back wall of the carriage there is a positioning sensor, which reads the information the printer needs from the encoder. The encoder serves as a kind of ruler with marks, thanks to which the printer prints images with great accuracy. It is not surprising that when this ruler became dirty, the printer head was, as they say, “lost.”

If your printer is installed, then encoder contamination will happen quite often. Some printer models (particularly Canon) refuse to print at all, displaying a carriage failure error. But now you can solve this problem yourself.

I cleaned the encoder with a clean cloth soaked in water. You can use an alcohol solution. Gently wipe the encoder on both sides along its entire length. For ease of operation, put the printer into cartridge replacement mode and, when the carriage reaches the middle, unplug the power cord. Now you can move the carriage left and right by hand and clean the entire length of the encoder.

When cleaning, do not overdo it, be careful. If you stretch it or damage it, you will have to look for a new encoder.

Cleaning took me less than five minutes, and immediately afterwards a printed photo showed that the printer was now in perfect working order.

For preventive purposes, I did the same procedure on the Epson T27, which I use for . Cleanliness won't hurt him either.

By the way, for such “repairs” in service center you would have to pay a considerable amount. But now you yourself know how fix carriage failure on your printer.

Valcoder on the control panel of the car radio

The roller should be disassembled carefully without using excessive force. The main task is to get to internal contacts and clean them from dirt and oxides. You can bend the moving contacts slightly so that they make better contact with the fixed contacts when sliding.

It is better to clean contacts using special means. For this you can use, for example, spray cleaner DEGREASER . It is easy to apply to the surface, evaporates quickly without leaving any traces, and cleans well from hardened rosin, oxides, dirt and fine dust. It is better to apply the spray on a toothbrush in a small amount and then carefully clean the surface of the internal contacts of the roller. After this, we assemble the encoder and solder it into the printed circuit board.

Usually, after such cleaning, the encoder operates stably and the problem with chaotic volume control no longer appears.

Order 343 mail. Order by Russian post. Consequences of failure to appear in court when summoned

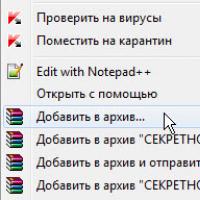

Order 343 mail. Order by Russian post. Consequences of failure to appear in court when summoned How to put a password on a folder on a Windows computer without and with programs

How to put a password on a folder on a Windows computer without and with programs Pluton – Free Bootstrap HTML5 One Page Template

Pluton – Free Bootstrap HTML5 One Page Template History of ZX Spectrum: Myths and reality New Spectrum

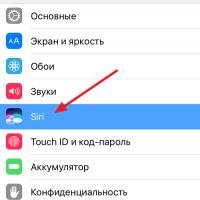

History of ZX Spectrum: Myths and reality New Spectrum Voice assistant Siri from Apple Siri functions on iPhone 6s

Voice assistant Siri from Apple Siri functions on iPhone 6s How to roll back to a previous version of iOS?

How to roll back to a previous version of iOS? Unlock iPad in four days

Unlock iPad in four days