How much does it cost to flash a washing machine? How to change the firmware of a washing machine

IN modern world Every home has a washing machine, which undoubtedly makes women's work easier and saves time. You can simply load dirty laundry into this unit, select the necessary program and continue to go about your business. But in some cases it is necessary to urgently turn off the machine. This can happen if dark clothes were mistakenly loaded into the machine with white laundry; during washing, foreign objects were found in the device, to remove which it is necessary to stop the operation of the unit, open it and remove all unnecessary items. Another reason for rebooting the washing machine is an incorrectly selected mode that needs to be changed. In this review, we will look at how to reset the program on a washing machine if a malfunction occurs.

How to stop the program

There are cases when, when choosing a washing mode, the program was selected incorrectly, or the machine freezes and is unable to correctly perform its intended purpose. If this happens, then you need to know the basic rules about resetting the selected program that can cope with the current situation. There is nothing complicated about this and basically you need to follow the same rules, which are identical for washing machines different models and brands. Necessary:

- Press the button that starts and stops the washing process.

- You need to wait until the unit stops.

- After this, you need to press this button again and wait 5 seconds.

- Relatively recent models of machines from the brands Indesit, Samsung and Bosch drain the water when you hold the “start” button and then turn off.

- Older units turn off without draining water.

It is necessary to take into account that if after all the manipulations the machine stops but does not drain the water, all the liquid must be drained manually. Some users believe that there is no need to press different buttons, because they can turn off the power to the washing machine. If you remove the plug from the socket, the device will actually turn off, but it is not a fact that the previously selected washing program will be reset. This is explained by the fact that for a long time developers have been equipping machines with technology that remembers the last selected washing mode if there is a power failure. Therefore, this method of solving the problem is not suitable.

Experts also do not recommend resetting the program by turning off the power to the washing machine for the reason that the unit may fail and in the end you will have to repair your assistant, which is not cheap, or buy a new one.

How to stop or restart the Indesit washing machine

Let's take a closer look at resetting washing modes for individual washing machine models. The method described above is not bad, but is not suitable for all models of this type household appliances because some of them do not have a start-stop button. In this case, the developers have provided a different way to stop and reset the washing settings. As for the Indesit brand, to start washing you need to turn the toggle switch and when selecting necessary program press the button. To reset the program you must:

- Press “start” and hold it for several seconds.

- The wash will stop.

- On older models, you also need to turn the toggle switch to the neutral position.

It is necessary to take into account that if the program reset on Indesit brand machines was successful, then all the lights should have turned green and immediately gone out. If there was no “blinking”, then there is a malfunction of the unit or some kind of error. Even if everything went correctly and successfully, the hatch may still not open due to large quantity water.

A reboot is not a change in the amount of laundry in the machine, but the establishment new program for washing. A reboot is necessary if:

- Inside washing machine a foreign object has fallen into the pocket - a phone, small change or other items in a clothing pocket.

- The wrong mode was selected and the washing process needs to be restarted.

- The unit has stopped or there has been a power failure.

- During washing, the machine freezes - the device does not respond to signals coming from the control panel.

The developers do not provide a special button to restart the Indesit brand washing machine. This function rests on the button that launches the program.

To stop the washing machine in order to change the operating mode, you must do the following:

- Press and hold the button that starts the program for 5 seconds.

- After the machine stops, select the desired mode.

- Add detergent again.

- Enable the program.

If you need to change the weight of the laundry in the drum, you need to drain the water using a special filter or spin mode.

How to stop LG, Samsung, Hotpoint-Ariston machines

On fairly old models of washing machines from South Korean companies LG and Samsung button There was no “start/stop”, so the washing program was started with a toggle switch. But these units are already quite rare, but still cope well with their functions.

Modern washing machines from LG and Samsung have a program reset button. You can press it while washing, and the machine itself will do everything necessary (stop the operation of the unit, drain the water and even open the hatch).

In this article, we explained how to reset your washing machine when necessary. Each device has such a feature, which is fully described in the operating instructions and is of a private nature. The main thing to remember is that you should never disconnect the device from the power supply, because this can lead to serious damage.

Questions - answers.

Q: What types of firmware does your program support for analyzing the firmware of Indesit and Ariston washing machines?

A: We present to your attention a program for analyzing the firmware of Indesit and Ariston washing machines on this moment accepts two types of firmware:

1. Firmware with a volume of 2048 bytes, intended for EVOI electronics. They are flashed into the external memory chip EEPROM 93С86;

2. Firmware with a volume of 8192 bytes, intended for EVOII electronics. Flashed into the external memory chip EEPROM 24C64;

Q: What is the firmware for Indesit and Ariston washing machines?

A: Firmware is a file with configuration data for specific model.

IN washing machines manufactured by Indesit Company with electronic platforms EVOI and EVOII, the firmware is written into an external memory chip - EPROM.

Variables for executing washing machine programs are also stored in this memory. That is, these firmwares contain two areas: variable data area And .

IN variable data areas When the washing machine operates, changes constantly occur that are necessary for the programs to run correctly.

In addition, operating statistics of the washing machine are recorded in this area.

IN configuration data area information about the washing machine itself is recorded.

This data does not change under any circumstances. If you change them, the machine will not work, primarily because the checksum will not match.

Q: What is a firmware checksum (CRC)?

A: If you add all the bytes together from the configuration data area (i.e., the immutable area), you will get some immutable sum. This amount is also written in the firmware file when designing the firmware, and the washing machine, when turned on, compares the CRC calculated and written.

If the CRCs are not equal, then the machine signals a memory error.

However, even if the CRC matches, this does not mean that the firmware is working.

Q: How are firmware file formats understood?

A: Although extensions (the end of a file name of three characters, separated from the main name by a dot) do not mean a specific format, since there is no specific standard, it is generally accepted that:

*.BIN - the data in the file is written in a direct stream;

*.EEP and *.DAT - the data in the file is written with inverted bytes in the word (a word in machine code is two bytes).

For example, here are excerpts of the contents of two identical files, but in different formats:

BIN:

Q: What firmware file formats does your program support for analyzing the firmware of Indesit and Ariston washing machines?

A: *.BIN - the data in the file is written in a direct stream;

*.E2P - the data in the file is written in a direct stream, but 152 bytes of service information are added by the programmer before the main data;

If your firmware file has an EEP or DAT extension, then in order to check it using our program, this file may have to be converted to BIN.

You can convert using a converter.

Attention! Archived files are not supported! Extract the firmware file from the archive (unzip the archive) and only then load it into our program.

Most often, flashing a washing machine is required when the electronic module fails. Are you sure that the diagnosis is correct, do you want to perform the operation yourself? We will show you how to flash a washing machine yourself.

Signs of a control module failure

- the corresponding error code on the display;

- panel indicators flash randomly;

- programs do not start or work incorrectly;

- the sequence of processes is confused, some stages are skipped;

- water temperature and washing time do not correspond to the prescribed mode;

- the engine spontaneously changes the number of revolutions;

- the drum changes direction of rotation for no reason.

To diagnose, you will have to remove the top cover of the washing machine and dismantle the front panel to get to the control board. After removing the board, verify the integrity of the microcircuit elements visually and by ringing with a multimeter. This video will guide you through the process of checking the control board:

After ensuring the integrity of the motherboard, the microcontroller, you can organize the preparation of firmware for washing machines. Pay attention to whether the module has equipment connection connectors. When there are none, software restored via the processor. For this, expensive, professional equipment is used, which is available in service centers.

Firmware for modules

To flash the car yourself via a laptop, you will need:

- laptop;

- electronic board of a failed machine;

- programmer with drivers;

- firmware program corresponding to the SMA modification.

The programmer is a special device that connects the module to the laptop. With its help, a program installed on a laptop (computer) restores command algorithms in the SMA memory.

Selecting a programmer for firmware

Professional devices of this type cost from 2000 to 4000 rubles. They can be purchased at spare parts stores for SM. Online stores sell inexpensive devices - up to 500 rubles, they are easy to use, without "tricks" or additional options, but with main function cope with a bang.

For each trademark A separate programmer is available. Drivers (if they are not included) and individual programs for SMA are freely available on specialized websites and developer pages. In particular, to reprogram the Indesit washing machine, a USBDM Memory Dump, the so-called Arcadia programmer, is used. It is suitable for platforms of the brands Electrolux, Whirlpool, Ariston.

If the control device breaks down, it is necessary to update the washing machine's firmware.

- A module in which the programming device is connected to the program download control;

- A module in which the programming device is not associated with the program download control;

- Module without control of program downloads, switching is possible by turning;

- Module with additional programs;

- Module with abbreviated programs;

- Electronic;

- Hybrid.

The hybrid control device is more reliable, works better, has a longer service life, as it is subject to less frequent breakdowns. Electronic control devices are sensitive to voltage surges, often reboot, stop working if there is a heavy load, and the operating time is short.

If the operation of the equipment has decreased with the frequency of downloads, the duration of the hours is confused when choosing modes, the machine begins to wash for a long time when choosing the fast mode, the programmer module needs to be loaded. The main thing is not to confuse a malfunction with its characteristics, for example, there is a category of machines that, when selecting a mode, begin to work slowly and “think” for a long time. There are machines that do not spin laundry well with a small number of loads; the laundry is distributed when wrung over the entire surface of the drum, and with a minimum of laundry, there is not enough for distribution. Each unit has its own characteristics, you should pay attention to this before flashing. Before flashing the machine, you need to test the module's command apparatus. If the test shows that there are malfunctions, then repairs are already necessary.

Before starting the firmware, you need:

- Control block;

- Computer or laptop;

- Programmer (external).

We connect the programmer on one side to the laptop, on the other to the board being flashed.

On the Internet we download software for a module of a specific model (for example, indesit) and install the driver on the laptop.The programmer can be bought both in a store and on the Internet. It is suitable for all models of units.

We download the software from the website of the manufacturer of a specific model.

Module flashing:

- Open the downloaded program;

- Open the USBDM tab, there should be the name of our device, if it’s not there, then the program “didn’t see it”;

- The Target/Device Selection tab should contain the number of the board being flashed;

- Next, click Load hex files, the software is downloading;

- Click program flash, the firmware is downloaded. The duration of the firmware depends on the specific model. For example, when flashing the board of an Indesit unit, the duration of firmware downloads is short.

If the control unit program was not loaded successfully, then it is necessary to check, firstly, all connected wires and reconnect the devices. It is also possible that the board has burned out.

In this case, it is necessary to carry out repairs, call a specialist, or go to the specialist yourself.The board itself is expensive, so it is better to try to have it repaired by a specialist; if it is absolutely impossible to repair it, then you will have to buy it in a specialized store, or order it from an online store. And the category of module repair work itself is very complex, it can only be done if you have certain skills in this matter, so if there is incompetence, it is better to immediately contact a specialist.

Why does the firmware on a washing machine crash?

Operation of the control board of the unit Indesit, Veko, Hayer, etc. is violated for several reasons:

- Network interruptions. Voltage surges have a bad effect on the operation of the Indesit, Veko, etc. washing machines, since they have weak control modules and do not have any protection against voltage surges;

- Mechanical damage. Upon impact, the control program may be disrupted;

- When purchasing, errors in the software may be discovered, that is, the manufacturer himself may have installed the firmware incorrectly.

- A heating element. It suffers mainly from scale and plaque, so it is necessary to periodically wash without laundry, with citric acid;

- Intelligent control. Suffering from power surges. In such cases, it is necessary to call a technician and change the control unit;

- Filter. May be faulty due to the fact that it may become clogged. It is also necessary to periodically clean the filter;

- Bearings. Over time and with maximum load, they wear out. Therefore, during long-term use, it is better to replace them, otherwise the drum may be damaged;

- Belt. It can wear and tear over time;

- Shock absorbers. They have the ability to wear out. This is not noticeable when washing clothes; it is noticeable when the machine starts spinning. A strong knocking sound is heard from the drum.

Do not consider the emanating unpleasant odor as a malfunction. The smell occurs when the equipment is not used for a long time, and a certain amount of water always remains in the washing machine after washing; over time, it rots and begins to smell. In this case, you need to do a dry wash with citric acid, then the smell will disappear.

Many people also consider it a malfunction if the machine starts tearing things. In this case, it is necessary to check the drum for the presence of sharp objects; it could be a pin, nail, or blade. This category of items is dangerous and may cause damage.

How to choose a programmer for firmware

There are two options: buy or make it yourself. Making a homemade device for firmware is risky. Firstly, you can damage the control board, and secondly, when buying spare parts for manufacturing, you can spend the same amount of money as when buying a finished device. Of course, you can buy non-original spare parts, but most likely such a device will quickly break down, and this again means a transfer of funds. It is better to buy original spare parts, since they are manufactured using a certain technology and by experienced specialists, and all parts are tested. And if you still can’t assemble the device, then it’s just “throwing money away.” Therefore, it is better to buy a professional device, there is less risk that something will not work out, and such a programmer is made by masters and has been tested during operation.

Many people wonder what is better when a program malfunctions: buy a new washing machine or repair old equipment. But at the same time, the repair of the control unit is carried out professionally, and the master will be able to sort out the module in such a way that in the end the performance will be better than before and will last a long time.

How to choose a repairman

When there is a breakdown, many people wonder which repairman is best to call: a private one or from an organization. And the quality of service is the same for both. The only advantage of the organization is that they have the capabilities to carry out complex repairs. Before the technician arrives, you must remove everything from the unit and remove the rug underneath (water may leak during inspection). You cannot take the machine out of the bathroom, since when checking the serviceability of the machine it is necessary that it be connected to the network and drained.

If the unit cannot be repaired, it can be handed over for recycling or there is a category of private advertisements for accepting a broken washing machine for spare parts.

/ Programming microcontrollers for electronic modules of washing machines

INDESIT, ARISTON with EVO-II hardware platform

This article describes the firmware technique internal memory microcontrollers (MK) used in power electronic modules (EM) and control panel boards (CP) of INDESIT/ARISTON washing machines (CM), made on the EVO-II hardware platform. The method under consideration is fair for programming MCU HD64F3694HV/3664H, which can be used in control units and modules designed to work with both 3-phase and commutator drive motors.

The electronic modules of the washing machine are made on the EVO-II hardware platform. Microcontrollers of the H8/300H family from RENESAS are used. MKs have a masked (write-once) ROM in which the boot loader, main software (software) and other information are stored. This memory should not be confused with a separate EEPROM chip (24C64), in which SM configuration data, statistical information, recorded error codes, etc. are recorded. Specialists were able to read the contents of the internal Read Only Memory Device of the non-volatile “brains” at a bitrate of 38400 baud (bit/s). Having the firmware file for the internal driver of the physical layer, it became possible to ensure replication on microcontrollers for use in electronic devices; in addition, it is not difficult to purchase these microcircuits (HD64F3694HV/3664H) with “clean” Flash memory.

Installing new microprocessors to replace failed ones has shown to be economically feasible; previously, in case of processor failures, it was necessary to change the entire module or use CHIPs from “donor” boards. Such electronic components in combination - processor + memory - can be programmed using standard clocked programmers. But this method is quite expensive, considering the cost of these programmers. There is also a method of uploading a program using ISP programmers (In-System Programming) directly on the electronic module board. This article discusses the technology of flashing processor Flash memory using a simple ISP programmer.

Rice. 1 Fundamental electrical diagram RS-232/TTL/CMOS level converters

For programming Micro Controller Unit will need: signal level converter(MAX232 chip - see Fig. 1), stabilized 5 V voltage source, thin insulated conductors and a regular electrical button (for short circuit). Also, for these purposes, a specialized program for flashing the FLASH memory of the microcontroller, called Flash Development Toolkit (FDT), is required. This program can be downloaded from the official RENESAS website www.renesas.com

Rice. 2 Section EM evo 2 with marked control points and connector J6

The first step is to do everything necessary connections. Figure 2 shows a section of one of the varieties of EV EVO-II (this module is designed to connect a commutator drive motor) with marked test points and jumper connector J6. The specified connector may be missing, but space for its installation on the printed circuit board is reserved. This is probably due to the fact that the manufacturer currently installs pre-firmware microcontrollers on the board and therefore there is no need to program them on the EM through the specified connector.

Rice. 5 Operating frequency of the quartz resonator is 4.91 MHz. Rice. 6 Selecting the baud rate

Jumper J6 provides communication when exchanging data between the programmable controller and the PC through a level converter (see Figure 1). The flash memory within the controller is programmed through this channel. J6 is connected to the microcontroller by the RXT/TXD line serial port UART. The purpose of the connector pins is as follows:

1

output - General duplex;

2

output - TXD data line;

3

output - RXD data reception line;

4

output - Power + 5 Volts.

Rice. 8. The process of data exchange between PC and MK. Rice. 9. The flash firmware process is completed without errors

To ensure the organization of throughput, two pins of the microcontroller with an exact time source are used: 7 (RESET, initial reset) and 35 (NMI, non-maskable interrupt). Due to certain difficulties when connecting directly to the MK terminals themselves, in Fig. 2 indicates the points on the EM board to which you can connect without the risk of damaging its pins:

- NMI, lower (see figure) terminal of resistor R10;

- RESET, left terminal of the ceramic SMD capacitor located below the quartz resonator.

The next step is to replace the faulty MK on the EV with a new one with “clean” FLASH memory firmware. Dismantling/installation of the microcircuit is performed by any of known methods(using a soldering station or hot air gun). After replacing the MK, the corresponding lines from the level converter are connected to connector J6 (see Fig. 1, the converter is also connected by a cable to the COM port of the PC). Then connect the 5 V power lines from a separate network source to the module (J6) and the level converter with parity bit and Break flow control.

Note. When programming the microprocessor, the module must be completely disconnected from all standard external connectors with the exception of connector J6.

Next, connect the NMI signal test point to the common wire (pin 1 of connector J6 or the middle pin of service connector J7). A RESET button is also connected to the control point (its second contact is connected to ground). The next step is to download from the website www.renesas.com and install the FDT 4.08 (Flash Development Toolkit) program.

Rice. 3 Start window of the FDT program in Basic. Rice. 4 Selecting a COM port

Launch the program in the “Basic” version (the program window is shown in Fig. 3). Next, select the connection type RS-232 or the MAX232 MK stream in the line (depending on the type of EM - 3664 or 3694) and click the “Next” button - a new window will appear (Fig. 4), in which you must specify the number of the COM port on the PC , to which the cable for communication with the processor is connected.

Once again, click the “Next” button and in the window that opens, enter the frequency of the microcontroller clock generator (the operating frequency of the external quartz resonator connected to the MK) - 4.910 (Fig. 5). After clicking “Next”, a window for selecting mode and speed will appear. Uncheck “Use Default” and select the maximum port speed (Fig. 6). Then click “Next” twice - a new window will appear (Fig. 7a), in which they indicate the path to the firmware file. To do this, check the “User/Data Area” box, click the arrow to the right of the line and then “Browse” (review), then select the firmware file (Fig. 7b).

Rice. 7 Selecting the firmware file

The name of the file can be different - it is not its name that is important, but its content, for example, the author used a file named processor_evo2_v2.74.bin (Fig. 7b). After selecting a file, the program window will look like shown in Fig. 7th century This step completes the program setup phase. Include external network adapter to the network (a voltage of 5 V is supplied to the level converter and the microcontroller) and then press the “Program Flash” button. The program begins sending requests to the module, as shown in Fig. 8. Within 1...2 s after pressing the “Program Flash” button, press and release the “Reset” button, after which the program will establish communication between personal computer and the microcontroller and the process of writing the Flash memory of the MK will begin.

It is possible that the first time it will not be possible to establish communication using the Universal Asynchronous Receiver-Transmitter: desktop computer and microprocessor. To solve this problem, you need to experiment with the duration of pressing the “Reset” button. If all the above operations were completed without errors, at the end of the recording process via the Serial Peripheral Interface (SPI) bus, the window shown in Fig. 9.

This completes the process of programming the MK's Flash memory. Remove the jumper from the NMI point and the RESET button, and unsolder the wires from connector J6 on the EM. After installing the electronic module in the washing machine using any of the known methods (using a programmer or through a service key), the EEPROM chip in its composition with configuration data, etc. is flashed.

The above-described firmware technique with a universal asynchronous transceiver (UART) is also valid for display modules (control panels, control panels) used in SMs made on the EVO-II platform.

The PU uses HD64x3661 MKs - they are from the same series as the MKs installed in power electronic modules, only they have a smaller amount of internal memory. MK PU are replaced with HD64X3664 without any modifications. The process of flashing the MK PU firmware is no different from that described above - it is even simpler, since all the main signals on the PU boards are output to special service connectors. As an example in Fig. 10 shows fragments printed circuit boards some types of control units, the location of control points on them and the assignment of contacts of service connectors.

Rice. 10 Location of service connector points and contacts on the boards.

In conclusion, here are the types of microcontrollers that can be used in washing machine modules:

- HD64F3694HV: it can be installed in EVs that include a TMS320LC(LF)2401A signal processor (in a 32-pin package) for working with 3-phase drive motors; -

HD64F3664H: it can be installed in all types of PU boards, on modules that work with commutator drive motors (Fig. 2), as well as on EMs that include a TMS320LC(LF)2402A signal processor (in a 64-pin package) for working with 3-phase drive motors.

Rice. 10. Location of control points on control panel boards and assignment of service connector contacts.

Order 343 mail. Order by Russian post. Consequences of failure to appear in court when summoned

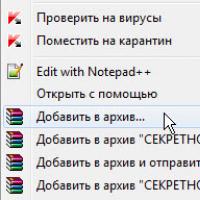

Order 343 mail. Order by Russian post. Consequences of failure to appear in court when summoned How to put a password on a folder on a Windows computer without and with programs

How to put a password on a folder on a Windows computer without and with programs Pluton – Free Bootstrap HTML5 One Page Template

Pluton – Free Bootstrap HTML5 One Page Template History of ZX Spectrum: Myths and reality New Spectrum

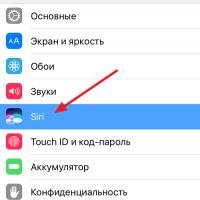

History of ZX Spectrum: Myths and reality New Spectrum Voice assistant Siri from Apple Siri functions on iPhone 6s

Voice assistant Siri from Apple Siri functions on iPhone 6s How to roll back to a previous version of iOS?

How to roll back to a previous version of iOS? Unlock iPad in four days

Unlock iPad in four days