Charging the battery from the computer power supply. Charger from a computer power supply. Accessory connector

The car battery needed charging. After going through several options, I settled on remaking the computer power supply. I decided to redo it in a simple way. The charger will not have adjustments; I have no such task. In principle, everything can be done in a couple of hours.

This power supply has a little-known chip 2003. There is little information on this microcircuit. It seems like this is a PWM controller with a multiviewer. We will understand the scheme, more about the scheme later.

I will connect to the battery using wires with crocodile clips. I already had them unsoldered.

I have a TV2-1 toggle switch as a power switch. Pulled it from an old TV.

The power supply circuit is quite simple. We have a 300-watt unit, a 250-watt circuit. The circuit may differ in the ratings of some components.

Assembly.

You need to remove all unnecessary components. It is marked in red that it needs to be desoldered. The 13 kOhm resistor is marked in yellow; we will replace it with 2.4 kOhm. Instead of the resistor marked in blue, we will temporarily install a variable resistor at 200 kOhm. It is advisable to set a variable resistor to 100 kOhm, but I didn’t have one. It took a long time to adjust the desired voltage.

The main thing is to set it to maximum resistance. There are also green tags, I’ll tell you what to connect to them later.

Solder off the excess components. Everything is legible on the diagram. It turns out the board is like this. Temporarily removed the power diodes. I also unsoldered the group stabilization choke, I will rewind it. A brown jumper connects the patches from the ground and PS-ON, which is necessary for startup.

We are interested in the +12 volt line. We put the power diode in place, I took the diode from the 5 volt line. The diode was installed without a gasket. The radiator mounting legs are not connected to the circuit, which eliminates short circuits. I installed an additional throttle, and in its place there was a jumper. I wound up all the windings from the old group stabilization choke, leaving the old winding at 12 volts. I installed a 1000 uF electrolytic capacitor with a voltage of 35 volts.

The variable resistor was placed on the wires outside the board.

Now we need to make a board - a decoy for our 2003 microcircuit. The decoy consists of three stabilizers at 3.3; 5; 12 volts. I soldered it according to a simple scheme. The upper two sections are assembled on TL431, the lower one on LM317.

The upper two sections of the circuit are connected to the lower section at 12 V. The scarf was made using the “scratching” technology. Done in 30 minutes.

The diagram indicated points for connecting the decoy board. Solder according to the diagram. On the diagram they are marked with green dots, respectively. The fake board has colors according to the voltages. It turned out something similar.

Using a variable resistor, we set the desired voltage at the output (I forgot to take a photo). I leave a freeze frame. I measure, the resistance of the resistor is about 11.7 kOhm. I assemble it from two resistors of 10 and 1.8 kOhm. The voltage changed slightly, but not significantly.

I screwed the “fake” board to the radiator through a bushing and an M3 screw. You can also see in the photo on the left that I installed back the load resistor R53.

I connected the wires with alligator clips. Installed an LED to indicate power on. I secured everything with hot glue. The network wire was put into a gap through a toggle switch.

Surely every car enthusiast has had to assemble a car charger with his own hands. There are a lot of different approaches, ranging from simple transformer circuits to pulse circuits with automatic adjustment. Charger from the computer power supply, it just occupies the golden mean. It comes at a cheap price, and its parameters do an excellent job of charging car batteries. Today we will tell you how in half an hour you can assemble a charger from computer unit ATX power supply. Go!

First you need a working power supply. You can take a very old one with 200 - 250 W, this power will be enough with a reserve. Considering that charging should occur at a voltage of 13.9 - 14.4 V, the most important modification in the unit will be raising the voltage on the 12 V line to 14.4 V. A similar method was used in the article: Charger from a power supply for LED strips.

Attention! In a working power supply, the elements are under dangerous voltage. Don't grab everything with your hands.

First of all, we unsolder all the wires that came out of the power supply. We leave only the green wire; it must be soldered to the negative contacts. (The areas from which the black wires came out are a minus.) This is done to automatically start the unit when connected to the network. I also immediately recommend soldering the wires with terminals to the negative and + 12 V bus (former yellow wires), for convenience and further setup of the charger.

The following manipulations will be performed with the PWM operating mode - for us it is a TL494 microcircuit (there are also a bunch of power supplies with its absolute analogues). We are looking for the first leg of the microcircuit (the lowest left leg), then we look at the track on the back of the board.

Three resistors are connected to the first pin of the microcircuit; we need the one that connects to the pins of the +12 V block. In the photo, this resistor is marked with red varnish.

This resistor must be unsoldered from the board and its resistance measured. In our case it is 38.5 kOhm.

Instead, you need to solder a variable resistor, which you first set to the same resistance of 38.5 kOhm.

By gradually increasing the resistance of the variable resistor, we achieve an output voltage of 14.4 V.

Attention! For each power supply, the value of this resistor will be different, because The circuits and details in the blocks are different, but the algorithm for changing the voltage is the same for everyone. When the voltage rises above 15 V, PWM generation may be disrupted. After this, the unit will have to be rebooted, after first reducing the resistance of the variable resistor.

In our unit, it was not possible to immediately increase the voltage to 14 V, the resistance of the variable resistor was not enough, so we had to add another constant one in series with it.

When the voltage of 14.4 V is reached, you can safely remove the variable resistor and measure its resistance (it was 120.8 kOhm).

The resistor measurement field must be selected constant resistor with as close a resistance as possible.

We made it up from two 100 kOhm and 22 kOhm.

We are testing the work.

At this stage, you can safely close the lid and use the charger. But if you wish, you can connect a digital voltammeter to this unit, this will give us the opportunity to monitor the charging progress.

You can also screw on the handle for easy carrying and cut a hole in the lid for a digital device.

The final test, we make sure that everything is assembled correctly and works well.

Attention! This charger retains the function of short circuit and overload protection. But it does not protect against overturning! Under no circumstances should you connect the battery to the charger with the wrong polarity; the charger will instantly fail.

When converting a power supply into a charger, it is advisable to have a circuit diagram on hand. To make life easier for our readers, we have made a small selection of ATX computer power supply diagrams.

To protect against polarity reversal, there are many interesting schemes. One of them can be found in this article.

Comments powered by HyperComments

diodnik.com

A battery charger from a power supply is a useful and inexpensive device in half an hour

To recharge the battery the best option- ready-made charger (charger). But you can do it yourself. There are many different ways assembling a homemade memory: from the most simple circuits using a transformer, to pulse circuits with the possibility of adjustment. The medium in complexity of implementation is the memory from a computer power supply. The article describes how to make a charger from a computer power supply for a car battery with your own hands.

Homemade charger from a power supply

Homemade charger from a power supply

Converting a computer power supply into a charger is not difficult, but you need to know the basic requirements for chargers designed to charge car batteries. For a car battery, the charger must have the following characteristics: the maximum voltage supplied to the battery must be 14.4 V, the maximum current depends on the charger itself. These are the conditions that are created in the electrical system of a car when the battery is recharged from a generator (video author Rinat Pak).

Tools and materials

Taking into account the requirements described above, to make a charger with your own hands, you first need to find a suitable power supply. A used ATX in working condition with a power of 200 to 250 W is suitable.

We take as a basis a computer that has the following characteristics:

- output voltage 12V;

- rated voltage 110/220 V;

- power 230 W;

- the maximum current value is not more than 8 A.

Tools and materials you will need:

- soldering iron and solder;

- screwdriver;

- 2.7 kOhm resistor;

- 200 Ohm and 2 W resistor;

- 68 Ohm resistor and 0.5 W;

- resistor 0.47 Ohm and 1 W;

- resistor 1 kOhm and 0.5 W;

- two 25 V capacitors;

- 12V automotive relay;

- three 1N4007 diodes 1 A;

- silicone sealant;

- green LED;

- voltammeter;

- "crocodiles";

- flexible copper wires 1 meter long.

Having prepared everything necessary tools and spare parts, you can start making a charger for the battery from the computer power supply.

Algorithm of actions

The battery should be charged under voltage in the range of 13.9-14.4 V. All computers operate with a voltage of 12V. Therefore, the main task of the modification is to increase the voltage coming from the power supply to 14.4 V. The main modification will be carried out with the PWM operating mode. The TL494 chip is used for this. You can use a power supply with absolute analogues of this circuit. This scheme used to generate pulses and also as a driver of a power transistor, which performs the function of protection against high currents. To regulate the voltage at the output of the computer power supply, the TL431 chip, which is installed on an additional board, is used.

Additional board with TL431 chip

Additional board with TL431 chip There is also a resistor for tuning, which makes it possible to adjust the output voltage in a narrow range.

Work on remaking the power supply consists of the following stages:

- To make modifications to the block, you first need to remove all unnecessary parts from it and unsolder the wires. What is superfluous in this case is the 220/110 V switch and the wires going to it. The wires should be unsoldered from the power supply. The unit requires a voltage of 220 V to operate. By removing the switch, we will eliminate the possibility of the unit burning out if the switch is accidentally switched to the 110 V position.

- Next, we unsolder, bite off unnecessary wires, or use any other method to remove them. First, we find the blue 12V wire coming from the capacitor and solder it. There may be two wires, both need to be unsoldered. We only need a bunch of yellow wires with a 12 V output, leaving 4 pieces. We also need ground - these are black wires, we also leave 4 of them. In addition, you need to leave one green wire. The remaining wires are completely removed or soldered.

- On the board along the yellow wire we find two capacitors in a circuit with a voltage of 12V, they usually have a voltage of 16V, they must be replaced with 25V capacitors. Over time, capacitors become unusable, so even if the old parts are still in working order, it is better to replace them.

- At the next stage, we need to ensure that the unit operates every time it is connected to the network. The fact is that the power supply in a computer works only if the corresponding wires in the output bundle are short-circuited. In addition, overvoltage protection must be excluded. This protection is installed in order to disconnect the power supply from the electrical network if the output voltage supplied to it exceeds a specified limit. It is necessary to exclude the protection, since the computer is allowed a voltage of 12 V, and we need to get 14.4 V at the output. For the built-in protection, this will be considered overvoltage and it will turn off the unit.

- The overvoltage shutdown action signal, as well as the on and off signals, pass through the same optocoupler. There are only three optocouplers on the board. With their help, communication is carried out between the low-voltage (output) and high-voltage (input) parts of the power supply. To prevent the protection from tripping during overvoltage, you need to close the contacts of the corresponding optocoupler with a solder jumper. Thanks to this, the unit will be on all the time if it is connected to the electrical network and will not depend on what voltage is at the output.

Solder jumper in red circle

Solder jumper in red circle - At the next stage, we need to achieve an outgoing voltage of 14.4 V when operating at idle, because the voltage on the power supply is initially 12 V. For this we need a TL431 chip, which is located on an additional board. Finding her won't be difficult. Thanks to the microcircuit, the voltage is regulated on all tracks that come from the power supply. The tuning resistor located on this board allows you to increase the voltage. But it allows you to increase the voltage value to 13 V, but it is impossible to get a value of 14.4 V.

- It is necessary to replace the resistor that is connected to the network in series with the trimming resistor. We are replacing it with a similar one, but with lower resistance - 2.7 kOhm. This makes it possible to expand the output voltage setting range and obtain an output voltage of 14.4 V.

- Next you need to start removing the transistor, which is located near the TL431 chip. Its presence may affect correct work TL431, that is, it may interfere with maintaining the output voltage at the required level. In the red circle is the location where the transistor was located.

Transistor location

Transistor location - Then, to obtain a stable output voltage at idle, it is necessary to increase the load on the power supply output through the channel, where the voltage was 12 V, but will become 14.4 V, and through the 5 V channel, but we do not use it. A resistor with a resistance of 200 Ohms and a power of 2 W will be used as a load for the first 12 V channel, and a 5 V channel will be supplemented for the load with a resistor with a resistance of 68 Ohms and a power of 0.5 W. Once these resistors are installed, the no-load no-load output voltage can be adjusted to 14.4V.

- Next you need to limit the output current. It is individual for each power supply. In our case, its value should not exceed 8 A. To achieve this, you need to increase the value of the resistor in the primary circuit of the winding power transformer, which is used as a sensor used to determine overload. To increase the value, the installed resistor must be replaced with a more powerful one with a resistance of 0.47 Ohms and a power of 1 W. After this replacement, the resistor will function as an overload sensor, so the output current will not exceed 10 A even if the output wires are shorted, simulating a short circuit.

Resistor to replace

Resistor to replace - At the last stage, you need to add a circuit to protect the power supply from connecting the charger to the battery with the wrong polarity. This is the circuit that will really be created with your own hands and is not included in the computer power supply. To assemble the circuit, you will need a 12 V automotive relay with 4 terminals and 2 diodes rated for 1 A, for example, 1N4007 diodes. In addition, you need to connect a green LED. Thanks to the diode, it will be possible to determine the charging status. If it lights up, it means the battery is connected correctly and is charging. In addition to these parts, you also need to take a resistor with a resistance of 1 kOhm and a power of 0.5 W. The figure shows the protection circuit.

Power supply protection circuit

Power supply protection circuit - The operating principle of the circuit is as follows. The battery with the correct polarity is connected to the output of the charger, that is, the power supply. The relay is activated due to the energy remaining in the battery. After the relay operates, the battery begins to charge from the assembled charger through closed contact BP relyushki. Charging confirmation will be indicated by a glowing LED.

- To prevent overvoltage that occurs when the coil is turned off due to the electromotive force of self-induction, a 1N4007 diode is connected to the circuit in parallel with the relay. It is better to glue the relay to the power supply heatsink with silicone sealant. Silicone remains elastic after drying and is resistant to thermal stress, such as compression and expansion, heating and cooling. When the sealant dries, the remaining elements are attached to the relay contacts. Instead of sealant, bolts can be used as fasteners.

Installation of the remaining elements

Installation of the remaining elements - It is better to choose wires for the charger of different colors, for example, red and black. They should have a cross-section of 2.5 square meters. mm, be flexible, copper. The length must be at least a meter. The ends of the wires must be equipped with crocodiles and special clamps with which the charger is connected to the battery terminals. To secure the wires in the body of the assembled device, you need to drill appropriate holes in the radiator. You need to thread two nylon ties through them, which will hold the wires.

Ready charger

Ready charger To control the charging current, you can also install an ammeter into the charger body. It must be connected in parallel to the power supply circuit. As a result, we have a charger that we can use to charge the car battery and more.

Conclusion

The advantage of this charger is that the battery will not be recharged when using the device and will not deteriorate, no matter how long it is connected to the charger.

The disadvantage of this charger is the absence of any indicators by which one could judge the state of charge of the battery.

It is difficult to determine whether the battery is charged or not. You can calculate the approximate charging time by using the readings on the ammeter and applying the formula: current in Amperes multiplied by time in hours. It was experimentally found that it takes 24 hours, that is, a day, to fully charge a conventional battery with a capacity of 55 A/h.

This charger retains the function of overload and short circuit. But if it is not protected from reverse polarity, you cannot connect the charger to a battery with the wrong polarity, the device will fail.

AvtoZam.com

Charger from a computer power supply

Hello everyone, today I will tell you how to make a charger for a car battery with your own hands from a computer power supply. So, we take the power supply and remove the top cover or simply disassemble it. We look for a chip on the board and look carefully at it, or rather at its designation, if you find a TL494 or KA7500 chip (or their analogues) there, then you are very lucky and we can You can easily remake this power supply without any additional hassles. We disassemble the power supply, take out the board and unsolder all the wires from it, we will no longer need them. To charge the battery normally, we should increase the output voltage of the power supply, since 12 volts for charging is not enough, we need about 14.4 volts.

We do this, take a tester and use it to find five volts that are suitable for the 13, 14 and 15 legs of the microcircuit and cut the trace, by doing this we turn off the power supply’s protection against voltage increases. And accordingly, when the block is connected to the network, it will turn on immediately. Next, we find 1 leg on the microcircuit, following this path we find 2 resistors and remove them, in my case these are resistors R2 and R1. In their places we solder variable resistors. One adjustable resistor with a handle is 33 Kom, and the second for a screwdriver is 68 Kom. Thus, we have achieved that we can now regulate the voltage at the output over a wide range.

It should look something like the photo. Next, we take a piece of wire, one and a half meters long and with a cross-section of 2.5 squares, we clean it from the sheath. Then we take two crocodiles and solder our wires to them. It is advisable to install a 10 amp fuse on the positive wire.

Now we find + 12 volts and ground on the board, and solder the wires to them. Next, connect the tester to the power supply. Set the variable resistor knob to the left position, using the second resistor (which is under the screwdriver), rotating it to set the lower voltage value to 14.4 volts. Now, by rotating the variable resistor, we can see how our voltage rises, but now it will not drop below 14.4 volts. This completes the block setup.

We begin assembling the power supply. We screw the board into place. For beauty, I installed LED lighting inside. If you install like me LED strip, then don’t forget to solder a 22 Ohm resistor in series with it, otherwise it will burn out. Also install a 22 Ohm resistor on the fan in the gap of any wire.

I installed a variable resistor on a PCB plate and brought it out. It is needed to adjust the strength of the output current by increasing the voltage at the output; in short, the larger the battery capacity, the more we turn the knob to the right. When I assembled everything, I secured the wires with hot glue. This is how the charger turned out. Now you will not have problems charging the battery.

xn--100--j4dau4ec0ao.xn--p1ai

Car charger from computer power supply

power unit personal computer Without much difficulty, it can be converted into a car charger. It provides the same voltage and current as when recharging from the car’s standard electrical outlet. The scheme is devoid of homemade printed circuit boards and is based on the concept of maximum ease of modification.

The basis was taken from a personal computer power supply with the following characteristics:

Rated voltage 220/110 V; - output voltage 12 V; - power 230 W;

The maximum current is no more than 8 A.

So, first you need to remove all unnecessary parts from the power supply. They are a 220 / 110 V switch with wires. This will prevent the device from burning out if the switch is accidentally switched to the 110 V position. Then you need to get rid of all the outgoing wires, with the exception of a bundle of 4 black and 2 yellow wires (they are responsible for powering the device).

Next, you should achieve a result where the power supply will always work when connected to the network, and also eliminate overvoltage protection. The protection turns off the power supply if the outgoing voltage exceeds a certain specified value. This needs to be done because the voltage we need should be 14.4 V, instead of the standard 12.0 V.

The on/off signals and surge protection actions pass through one of three optocouplers. These optocouplers connect the low-voltage and high-voltage sides of the power supply. So, in order to achieve the desired result, we should close the contacts of the desired optocoupler using a solder jumper (see photo).

The next step is to set the output voltage to 14.4 V in idle mode. To do this, we are looking for a board with a TL431 chip. It acts as a voltage regulator on all outgoing tracks of the power supply. This board contains a trimming resistor that allows you to change the outgoing voltage in a small range.

The trim resistor may not be sufficient (since it allows you to increase the voltage to approximately 13 V). In this case, you need to replace the resistor connected in series with the trimmer with a resistor with lower resistance, namely 2.7 kOhm.

Then you should add a small load consisting of a resistor with a resistance of 200 Ohms and a power of 2 W to the output on the “12 V” channel and a resistor with a resistance of 68 Ohms, with a power of 0.5 W to the output on the “5 V” channel. In addition, you need to get rid of the transistor located next to the TL431 chip (see photo).

It was found that it prevents the voltage from stabilizing at the level we need. Only now, using the tuning resistor mentioned above, we set the output voltage to 14.4 V.

Next, in order for the output voltage to be more stable at idle, it is necessary to add a small load to the output of the unit along the +12 V channel (which we will have +14.4 V), and on the +5 V channel (which we do not use). A 200 Ohm 2 W resistor is used as a load on the +12 V channel (+14.4), and a 68 Ohm 0.5 W resistor is used on the +5 V channel (not visible in the photo, because it is located behind an additional board):

We also need to limit the current at the output of the device to 8-10 A. This current value is optimal for this power supply. To do this, you need to replace the resistor in the primary circuit of the power transformer winding with a more powerful one, namely 0.47 Ohm 1W.

This resistor acts as an overload sensor and the outgoing current will not exceed 10 A even if the output terminals are short-circuited.

The last step is to install a protection circuit to prevent the charger from being connected to the battery with the wrong polarity. To assemble this circuit, we will need a car relay with four terminals, 2 1N4007 diodes (or similar) as well as a 1 kOhm resistor and a green LED, which will indicate that the battery is connected correctly and is charging. The protection circuit is shown in the figure.

The scheme works on this principle. When the battery is correctly connected to the charger, the relay is activated and closes the contact using the energy remaining in the battery. The battery is charged from the charger, which is indicated by the LED. To prevent overvoltage from the self-induced emf that occurs on the relay coil when it is turned off, a 1N4007 diode is connected in parallel with the relay.

The relay with all elements is mounted to the charger radiator using bolts or silicone sealant.

The wires that are used to connect the charger to the battery must be flexible copper, multi-colored (for example, red and blue) with a cross-section of at least 2.5 mm? and about 1 meter long. It is necessary to solder crocodiles to them for convenient connection to the battery terminals.

I would also advise installing an ammeter into the charger body to monitor the charging current. It must be connected in parallel to the circuit “from the power supply”.

The device is ready.

The advantages of such a charger include the fact that when using it, the battery will not be recharged. The disadvantages are the lack of indication of the battery charge level. But to calculate the approximate battery charging time, you can use the data from the ammeter (current “A” * time “h”). In practice, it was found that within a day a battery with a capacity of 60 Ah can be charged 100%.

Tell friends:

xn----7sbbil6bsrpx.xn--p1ai

Charger from power supply from computer

It all started with the fact that they gave me an ATX power supply from a computer. So it sat in the stash for a couple of years until the need arose to build a compact battery charger. The unit is made on the TL494 chip, well-known for the series of power supplies, which makes it possible to easily convert it into a charger. I will not go into details of the operation of the power supply, the modification algorithm is as follows:

1. Clean the power supply from dust. You can use a vacuum cleaner, you can blow it with a compressor, whatever you have at hand. 2. We check its performance. To do this, in the wide connector that goes to motherboard computer, you need to find the green wire and jump it to minus (black wire), then turn on the power supply to the network and check the output voltages. If the voltage (+5V, +12V) is normal, proceed to step 3.

3. Disconnect the power supply from the network and remove the printed circuit board. 4. Solder extra wires, on the board we solder a jumper of the green wire and the minus wire. 5. We find a TL494 chip on it, maybe an analogue of the KA7500.

TL494 We unsolder all the elements from pins of the microcircuit No. 1, 4, 13, 14, 15, 16. A resistor and capacitor should remain on pins 2 and 3, we also solder everything else. Often 15-14 legs of the microcircuit are located together on one track, they need to be cut. You can cut the extra tracks with a knife, this will better eliminate installation errors.

Refinement scheme...

Refinement scheme...

Resistor R12 can be made with a piece of thick copper wire, but it is better to take a set of 10 W resistors connected in parallel or a shunt from a multimeter. If you install an ammeter, you can solder it to the shunt. It should be noted here that the wire from the 16th leg should be on the minus load of the power supply, and not on the total mass of the power supply! The correct operation of the current protection depends on this.

7. After installation, we connect an incandescent light bulb, 40-75 W 220V, in series to the unit via the power supply. This is necessary so as not to burn the output transistors if there is an installation error. And we turn on the block to the network. When you turn it on for the first time, the light should blink and go out, and the fan should work. If everything is fine, go to step 8.

8. Using a variable resistor R10, we set the output voltage to 14.6 V. Next, we connect a 12 V, 55 W car light bulb to the output and set the current so that the unit does not turn off when connecting a load of up to 5 A, and turns off when a load is more than 5 A. Current value may be different, depending on the dimensions of the pulse transformer, output transistors, etc... On average, 5 A will be used for a charger.

9. Solder the terminals and go to test the battery. As the battery charges, the charge current should decrease and the voltage should be more or less stable. The end of the charge will be when the current decreases to zero.

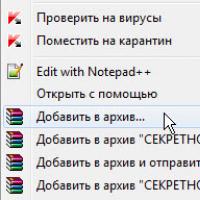

How to remove a program true key from computer

Computers cannot work without electricity. To charge them, special devices called power supplies are used. They receive AC voltage from the mains and convert it to DC. The devices can deliver enormous amounts of power in a small form factor and have built-in overload protection. Their output parameters are incredibly stable, and the quality direct current ensured even under high loads. When you have an extra device like this, it makes sense to use it for many household tasks, for example, by converting it from a computer power supply into a charger.

The block has the shape of a metal box with a width of 150 mm x 86 mm x 140 mm. As standard, it is mounted inside the PC case using four screws, a switch and a socket. This design allows air to flow into the cooling fan of the power supply unit (PSU). In some cases, a voltage selector switch is installed to allow the user to select the readings. For example, in the United States there is an internal power supply that operates at a nominal voltage of 120 volts.

A computer's power supply consists of several components inside: a coil, capacitors, an electronic board for regulating current, and a fan for cooling. The latter is the main cause of failure for power supplies (PS), which must be taken into account when installing a charger from an atx computer power supply.

Types of power supply for a personal computer

IPs have a certain power, indicated in watts. A standard unit is typically capable of delivering around 350 watts. The more components installed on the computer: hard drives, CD/DVD drives, tape drives, fans, the more energy is required from the power supply.

Experts recommend using a power supply that provides more power than the computer requires, as it will operate in a constant "underload" mode, which will increase the life of the machine due to the reduced thermal impact on its internal components.

There are 3 types of IP:

- AT Power Supply - used on very old PCs.

- ATX power supply - still used on some PCs.

- ATX-2 power supply - commonly used today.

Power supply parameters that can be used when creating a charger from a computer power supply:

- AT / ATX / ATX-2:+3.3 V.

- ATX / ATX-2: +5 V.

- AT / ATX / ATX-2: -5 V.

- AT / ATX / ATX-2: +5 V.

- ATX / ATX-2: +12 V.

- AT / ATX / ATX-2: -12 V.

Motherboard connectors

The IP has many different power connectors. They are designed in such a way that there is no mistake when installing them. To make a charger from a computer power supply, the user will not have to spend a lot of time choosing the right cable, since it simply won’t fit in the connector.

Types of connectors:

- P1 (PC/ATX connector). The main job of a power supply unit (PSU) is to provide power to the motherboard. This is done via a 20-pin or 24-pin connector. 24-pin cable is compatible with 20-pin motherboard.

- P4 (EPS socket): Previously, the motherboard pins were insufficient to support the processor power. With overclocking GPU, reaching 200 W, it was possible to provide power directly to the processor. Currently this is P4 or EPS which provides sufficient processor power. Therefore, converting the computer power supply into a charger is economically justified.

- PCI-E connector (6-pin 6+2). The motherboard can provide a maximum of 75W through the PCI-E interface slot. A faster dedicated graphics card requires much more power. To solve this problem, the PCI-E connector was introduced.

Cheap motherboards are equipped with a 4-pin connector. More expensive "overclocking" motherboards have 8-pin connectors. Additional ones provide excess processor power during overclocking.

Most power supplies come with two cables: 4-pin and 8-pin. Only one of these cables needs to be used. It is also possible to split the 8-pin cable into two segments to ensure backward compatibility with cheaper motherboards.

The left 2 pins of the 8-pin connector (6+2) on the right are disconnected to ensure backward compatibility with 6-pin graphics cards. The 6-pin PCI-E connector can supply an additional 75W per cable. If the graphics card contains a single 6-pin connector, it can be up to 150W (75W from motherboard + 75W from cable).

More expensive graphics cards require an 8-pin (6+2) PCI-E connector. With 8 pins, this connector can provide up to 150W per cable. A graphics card with a single 8-pin connector can handle up to 225W (75W from motherboard + 150W from cable).

Molex, a 4-pin peripheral connector, is used when creating a charger from a computer's power supply. These pins are very long lasting and can supply 5V (red) or 12V (yellow) to peripheral devices. In the past, these connections were often used to connect hard drives, CD-ROM players, etc.

Even GeForce 7800 GS video cards are equipped with Molex. However, their power consumption is limited, so nowadays most of them have been replaced by PCI-E cables and all that remains are powered fans.

Accessory connector

The SATA connector is a modern replacement for the outdated Molex. All modern DVD players, hard disks and SSDs run on SATA power. The Mini-Molex/Floppy connector is completely obsolete, but some PSUs still come with a mini-molex connector. These were used to power floppy drives with up to 1.44 MB of data. They have mostly been replaced by USB storage today.

Molex-PCI-E 6-pin adapter for powering the video card.

When using a 2x-Molex-1x PCI-E 6-pin adapter, you must first make sure that both Molexes are connected to different cable voltages. This reduces the risk of overloading the power supply. With the introduction of ATX12 V2.0, changes were made to the 24-pin system. The older ATX12V (1.0, 1.2, 1.2 and 1.3) used a 20-pin connector.

There are 12 versions of the ATX standard, but they are so similar that the user does not need to worry about compatibility when installing a charger from the computer's power supply. To ensure this, most modern sources allow you to disconnect the last 4 pins of the main connector. It is also possible to create advanced compatibility using an adapter.

Computer supply voltage

A computer requires three types of DC voltage. 12 volts is needed to supply voltage to the motherboard, graphic cards, for fans, processor. The USB ports require 5 volts, while the CPU itself uses 3.3 volts. 12 volts are also applicable for some smart fans. The electronic board in the power supply is responsible for sending converted electricity through special cable sets to power devices inside the computer. Using the components listed above, AC voltage is converted into pure DC current.

Almost half of the work done by a power supply is done with capacitors. They store energy that will be used for continuous work flow. When making a computer power supply, the user must be careful. Even if the computer is turned off, there is a chance that electricity will be stored inside the power supply in capacitors, even several days after the shutdown.

Cable kit color codes

Inside the power supplies, the user sees many cable sets coming out with different connectors and different numbers. Power cable color codes:

- Black, used to provide current. Every other color must be connected to the black wire.

- Yellow: +12V.

- Red: +5V.

- Blue: -12V.

- White: -5V.

- Orange: 3.3V.

- Green, control wire for checking DC voltage.

- Purple: +5V standby.

The output voltages of a computer's power supply can be measured using a proper multimeter. But due to the higher risk of short circuit, the user should always connect the black cable with the black one on the multimeter.

Power cord plug

The wire hard drive(regardless of whether it is IDE or SATA) has four wires attached to the connector: a yellow one, two black ones in a row, and a red one. The hard drive uses both 12V and 5V at the same time. 12V powers moving mechanical parts, while 5V supplies electronic circuits. So all these cable kits are equipped with 12V and 5V cables at the same time.

The electrical connectors on the motherboard for processors or chassis fans have four legs that support the motherboard for 12V or 5V fans. Besides the black, yellow, and red, other colored wires can only be seen in the main connector, which goes directly into the motherboard socket. These are purple, white or orange cables that are not used by consumers to connect peripheral devices.

If you want to make a car charger from a computer power supply, you need to test it. You will need a paperclip and about two minutes of time. If you need to reconnect the power supply to the motherboard, you just need to remove the paperclip. There will be no changes in it from using a paper clip.

Procedure:

- Find the green wire in the cable tree from the power supply.

- Follow it to a 20 or 24 pin ATX connector. The green wire is in a sense a “receiver”, which is needed to supply energy to the power supply. There are two black ground wires between it.

- Place the paperclip into the pin with the green wire.

- Place the other end into one of the two black ground wires next to the green one. It doesn't matter which one will work.

Although the paperclip will not produce a large shock, it is not recommended to touch the metal part of the paperclip while it is energized. If you need to leave a paperclip indefinitely, you need to wrap it with electrical tape.

If you start making a charger with your own hands from a computer power supply, take care of the safety of your work. The source of the threat is capacitors, which carry a residual charge of electricity that can cause significant pain and burns. Therefore, you need to not only make sure that the power supply is securely disconnected, but also wear insulating gloves.

After opening the power supply, they assess the workspace and make sure that there will be no problems with clearing the wires.

They first think through the design of the source, measuring with a pencil where the holes will be in order to cut the wires to the required length.

Perform wire sorting. In this case, you will need: black, red, orange, yellow and green. The rest are redundant, so they can be cut off on the circuit board. Green indicates power on after standby. It is simply soldered to the black ground wire, which will ensure that the power supply is turned on without a computer. Next you need to connect the wires to 4 large clamps, one for each set of colors.

After this, you need to group the 4-wire colors together and cut them to the required length, strip the insulation and connect them at one end. Before drilling holes, you need to take care of the chassis circuit board so that it is not contaminated with metal shavings.

Most PSUs cannot completely remove the PCB from the chassis. In this case, it must be carefully wrapped in a plastic bag. Having finished drilling, you need to treat all rough spots and wipe the chassis with a cloth to remove debris and plaque. Then install the retaining posts using a small screwdriver and clamps, securing them with pliers. After this, close the power supply and mark the voltage on the panel with a marker.

Charging a car battery from an old PC

This device will help the car enthusiast in difficult situation, when you urgently need to charge your car battery without having a standard device, but using only a regular PC power supply. Experts do not recommend constantly using a car charger from a computer power supply, since the voltage of 12 V is slightly below what is required when charging the battery. It should be 13 V, but it can be used as an emergency option. To increase the voltage where previously there was 12V, you need to change the resistor to 2.7 kOhm on the trimmer resistor installed on the additional power supply board.

Since power supplies have capacitors that store electricity for a long time, it is advisable to discharge them using a 60W incandescent lamp. To attach the lamp, use the two ends of the wire to connect to the cap terminals. The backlight will slowly go out, discharging the cover. Shorting the terminals is not recommended as this will cause a large spark and may damage the PCB traces.

The procedure for making a charger from a computer power supply with your own hands begins with removing the top panel of the power supply. If the top panel has a 120mm fan, disconnect the 2-pin connector from the PCB and remove the panel. You need to cut the output cables from the power supply using pliers. You shouldn’t throw them away; it’s better to reuse them for non-standard tasks. For each connecting post, leave no more than 4-5 cables. The rest can be trimmed on the PCB.

Wires of the same color are connected and secured using cable ties. The green cable is used to turn on the DC power supply. It is soldered to the GND terminals or connected to the black wire from the bundle. Next, measure the center of the holes on the top cover, where the fixing posts should be secured. You need to be especially careful if a fan is installed on the top panel, and the gap between the edge of the fan and the IP is small for the fixing pins. In this case, after marking the central points, you need to remove the fan.

After this, you need to attach the fixing posts to the top panel in the order: GND, +3.3 V, +5 V, +12 V. Using a wire stripper, the insulation of the cables of each bundle is removed, and the connections are soldered. Use a heat gun to heat the sleeves over the crimp connections, then insert the tabs into the connecting pins and tighten the second nut.

Next, you need to return the fan to its place, connect the 2-pin connector to the socket on the circuit board, insert the panel back into the device, which may require some effort due to the bundle of cables on the crossbars, and close it.

Charger for screwdriver

If the screwdriver has a voltage of 12V, then the user is lucky. It can make a power supply for the charger without much modification. You will need a used or new computer power supply. It has several voltages, but you need 12V. There are many wires of different colors. You will need yellow ones that output 12V. Before starting work, the user must make sure that the power source is disconnected from the power source and has no residual voltage in the capacitors.

Now you can start converting your computer's power supply into a charger. To do this, you need to connect the yellow wires to the connector. This will be the 12V output. Do the same for the black wires. These are the connectors into which the charger will be connected. In the block, 12V voltage is not primary, so a resistor is connected to the red 5V wire. Next you need to connect the gray and one black wire together. This is a signal that indicates energy supply. The color of this wire may vary, so you need to make sure it is the PS-ON signal. This should be written on the power supply sticker.

After turning on the switch, the power supply should start, the fan should rotate, and the light should light up. After checking the connectors with a multimeter, you need to make sure that the unit produces 12 V. If so, then the screwdriver charger from the computer power supply is functioning correctly.

In fact, there are many options for adapting the power supply to your own needs. Those who like to experiment are happy to share their experiences. Here are some good tips.

Users shouldn't be afraid to upgrade the unit's box: they can add LEDs, stickers, or anything else they need to upgrade it. When disassembling the wires, you need to make sure that you are using an ATX power supply. If it's an AT or older power supply, it will most likely have a different color scheme for the wires. If the user does not have information about these wires, he should not re-equip the unit, since the circuit may be assembled incorrectly, which will lead to an accident.

Some modern power supplies have a communication wire that must be connected to the power supply for it to work. The gray wire connects to the orange and the pink wire to the red. A high wattage power resistor may become hot. In this case, you need to use a radiator for cooling in the design.

The power supply of a personal computer can be converted into a car charger without much difficulty. It provides the same voltage and current as when recharging from the car’s standard electrical outlet. The circuit is devoid of homemade printed circuit boards and is based on the concept of maximum ease of modification.

The basis was taken from a personal computer power supply with the following characteristics:

– rated voltage 220/110 V;

– output voltage 12 V;

– power 230 W;

– maximum current no more than 8 A.

So, first you need to remove all unnecessary parts from the power supply. They are a 220 / 110 V switch with wires. This will prevent the device from burning out if the switch is accidentally switched to the 110 V position. Then you need to get rid of all the outgoing wires, with the exception of a bundle of 4 black and 2 yellow wires (they are responsible for powering the device).

Next, you should achieve a result where the power supply will always work when connected to the network, and also eliminate overvoltage protection. The protection turns off the power supply if the outgoing voltage exceeds a certain specified value. This needs to be done because the voltage we need should be 14.4 V, instead of the standard 12.0 V.

The on/off signals and surge protection actions pass through one of three optocouplers. These optocouplers connect the low-voltage and high-voltage sides of the power supply. So, in order to achieve the desired result, we should close the contacts of the desired optocoupler using a solder jumper (see photo).

The next step is to set the output voltage to 14.4 V in idle mode. To do this, we are looking for a board with a TL431 chip. It acts as a voltage regulator on all outgoing tracks of the power supply. This board contains a trimming resistor that allows you to change the outgoing voltage in a small range.

The trim resistor may not be sufficient (since it allows you to increase the voltage to approximately 13 V). In this case, you need to replace the resistor connected in series with the trimmer with a resistor with lower resistance, namely 2.7 kOhm.

Then you should add a small load consisting of a resistor with a resistance of 200 Ohms and a power of 2 W to the output on the “12 V” channel and a resistor with a resistance of 68 Ohms, with a power of 0.5 W to the output on the “5 V” channel. In addition, you need to get rid of the transistor located next to the TL431 chip (see photo).

It was found that it prevents the voltage from stabilizing at the level we need. Only now, using the tuning resistor mentioned above, we set the output voltage to 14.4 V.

Next, in order for the output voltage to be more stable at idle, it is necessary to add a small load to the output of the unit along the +12 V channel (which we will have +14.4 V), and on the +5 V channel (which we do not use). A 200 Ohm 2 W resistor is used as a load on the +12 V channel (+14.4), and a 68 Ohm 0.5 W resistor is used on the +5 V channel (not visible in the photo, because it is located behind an additional board):

We also need to limit the current at the output of the device to 8-10 A. This current value is optimal for this power supply. To do this, you need to replace the resistor in the primary circuit of the power transformer winding with a more powerful one, namely 0.47 Ohm 1W.

This resistor acts as an overload sensor and the outgoing current will not exceed 10 A even if the output terminals are short-circuited.

The last step is to install a protection circuit to prevent the charger from being connected to the battery with the wrong polarity. To assemble this circuit, we will need a car relay with four terminals, 2 1N4007 diodes (or similar) as well as a 1 kOhm resistor and a green LED, which will indicate that the battery is connected correctly and is charging. The protection circuit is shown in the figure.

The scheme works on this principle. When the battery is correctly connected to the charger, the relay is activated and closes the contact using the energy remaining in the battery. The battery is charged from the charger, which is indicated by the LED. To prevent overvoltage from the self-induced emf that occurs on the relay coil when it is turned off, a 1N4007 diode is connected in parallel with the relay.

The wires that are used to connect the charger to the battery must be flexible copper, multi-colored (for example, red and blue) with a cross-section of at least 2.5 mm? and about 1 meter long. It is necessary to solder crocodiles to them for convenient connection to the battery terminals.

I would also advise installing an ammeter into the charger body to monitor the charging current. It must be connected in parallel to the circuit “from the power supply”.

The device is ready.

The advantages of such a charger include the fact that when using it, the battery will not be recharged. The disadvantages are the lack of indication of the battery charge level. But to calculate the approximate battery charging time, you can use the data from the ammeter (current “A” * time “h”). In practice, it was found that within a day a battery with a capacity of 60 Ah can be charged 100%.

Order 343 mail. Order by Russian post. Consequences of failure to appear in court when summoned

Order 343 mail. Order by Russian post. Consequences of failure to appear in court when summoned How to put a password on a folder on a Windows computer without and with programs

How to put a password on a folder on a Windows computer without and with programs Pluton – Free Bootstrap HTML5 One Page Template

Pluton – Free Bootstrap HTML5 One Page Template History of ZX Spectrum: Myths and reality New Spectrum

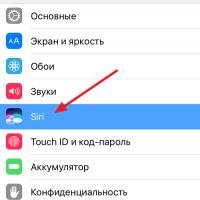

History of ZX Spectrum: Myths and reality New Spectrum Voice assistant Siri from Apple Siri functions on iPhone 6s

Voice assistant Siri from Apple Siri functions on iPhone 6s How to roll back to a previous version of iOS?

How to roll back to a previous version of iOS? Unlock iPad in four days

Unlock iPad in four days