Epson print head cleaning fluid. Methods for resuscitating a dried out print head. ■ cleaning ■ red ■ designed for external plastic surfaces

Flushing fluid Korean made Ink-Mate (Cleaning Solution) used in washing print heads (PG) of MFPs and Epson printers.

The liquid contains special substances that easily cope with dried pigment and water-soluble inks. In addition, they do an excellent job of washing out various types of debris accumulated in the print heads of Epson devices. Also during printing on MFPs and printers with PLC or CISS With low-quality ink, you should regularly wash the Epson ink. Flushing liquid is also used in cases where there is a transition from one type of ink to another.

IN MFPs and Epson PG printers is one of the most expensive elements. If the MFP or printer has not been used for a long time, or low-quality ink has been used, then to maintain the print head in working condition, it must be washed regularly. In this case, it will not fail.

If the inkjet printer is not used for a long time, the ink will begin to dry out. Unprinted areas may appear on the sheets during printing. If standard cleaning of the MFP or printer using a computer does not lead to a positive result, then you can use cleaning fluid Ink-Mate Cleaning Solution.

You pay in cash to the courier or in our office. You are given documents for reporting (check, sales receipt, invoice, delivery notes, etc.). On the ordering page, select “Cash payment”, payment is made upon receipt of the order.

Bank card (Online).You can pay anyone by bank card(VISA, MasterCard, VISA Electron, Maestro), after placing the order. If you have chosen to pay by card, you will be redirected to the bank's secure website, where you will enter your details and make the payment immediately.

Bank card.You can pay by any bank card (VISA, MasterCard, VISA Electron, Maestro) to the courier or in our office through the terminal. Payment occurs upon receipt of the order.

Cashless payments for legal entities.When you confirm your order, you will receive an invoice via email, with which you can pay from your organization’s bank account. We have a simplified taxation system, we work without VAT. When the bank transfers money to our current account, we contact you and clarify the information on the order. The original invoice or delivery notes are sent to you with your order.

After placing your order, an invoice with our payment details will be sent to your email. You can pay at any bank.

QIWI. When placing an order, you must indicate the phone number to which QIWI is linked. After placing your order, you will be redirected to the QIWI website, where you will pay for the order. If it is convenient for you to make payments using QIWI terminals, then you can also do this.

Yandex. Money. After placing your order, you will be redirected to “Yandex.Money”, where you will make payment. There should be money in your Yandex.Money account that you can spend on our website. No money will be debited from a card linked to a Yandex account.

Possible only if you have chosen delivery by Russian Post. You pick up your parcel at your branch and pay for delivery, the cost of the goods and the Russian Post commission.

IN section "PAYMENT"

Courier in Moscow.We deliver your order by courier at a time convenient for you. If you placed an order before 17-00, The courier delivers the order on the next working day. Express delivery is possible for an additional fee. (Monday - Saturday)

Courier in the Moscow region.We deliver your order by courier at a time convenient for you. The courier delivers the order within 1-3 working days. (Monday - Saturday)

You can receive your order at any time work time in the office, which is located 5 minutes walk from the station. Perovo metro station. We work from Monday to Saturday, check the time with our managers by phone or on the website at the bottom of the page.

Post office. You will receive your order at the post office. We deliver to our post office within 2-3 business days. You can find out the exact delivery times on the official website of Russian Post. You can track your order on our main website - ThePrint.ru. The site calculates shipping costs automatically.

EMS. Delivery of the order to your address. We deliver to our post office within 2-3 working days. You can find out the exact delivery times on the official website of Russian Post. The site calculates shipping costs automatically.

Transport company.We deliver to the transport company within 2-3 working days. Delivery transport companies You pay yourself when you receive your order. You can track your order and find out the exact delivery times on the websites of transport companies.

IN "DELIVERY" section , You can read more details.

Hello, dear friends.

Data-medium-file="https://refitrf.ru/wp-content/uploads/cl-178x300.jpg" data-large-file="https://refitrf.ru/wp-content/uploads/cl. .jpg" alt="How to flush an inkjet printer" width="127" height="214" srcset="https://refitrf.ru/wp-content/uploads/cl..jpg 89w, https://refitrf.ru/wp-content/uploads/cl-178x300.jpg 178w" sizes="(max-width: 127px) 100vw, 127px">О том как промыть СНПЧ, ПЗК, ПГ (печатающую головку) принтера я уже рассказывал и отснял не одно видео. В этот раз пойдет речь о том, как самостоятельно изготовить промывочную жидкость и как ее применять в различных вариантах, т.е. для промывки ПГ, системы СНПЧ и так далее. Прежде чем посмотреть видео, обязательно дочитайте до конца текст, так как в нем не все рассказано. Жидкость, которую я изготавливаю ни в коем случае не является панацеей от всех бед. К сожалению, таковой я еще не встречал, даже самые мощные из представленных на рынке не гарантируют хороший результат!!!!}

What would you like to add? Over the many years of work, I have not been able to try anything as a cleaner for the PG (I mainly work with Epson) and I have never been able to discover something truly ideal and, moreover, safe for the PG printer. Powerful liquids, as a rule, can damage the steam generator without completely flushing everything out, and ordinary liquids often cannot cope with light blockages. The video shows the liquid that I make from a glass and mirror cleaner, which is the well-known Mister Muscle, who is also not ideal, although it cleans simple blockages remarkably well. Now it is disappearing from sale and I had to look for a replacement. A couple of years ago I found it and slightly modified it, preparing a quite passable solution. It is not suitable for serious blockages. In such cases, I prepare another, more serious option, but more on that later.

What was missing in the video (I just forgot to tell you)?

- All operations involving the extraction of PG, and especially its washing, must be done extremely carefully. A microdrop of liquid or water on the contacts or board of the PG itself (or on the cable) is enough to destroy the result of very painstaking work in flushing! Both the PG itself and the printer formatter can burn out.

- If during the washing process you see that when you press liquid under pressure in one color, it flows out of the intake holes of another (see video), stop working, this is irreparable. Very often this can be understood by the nozzle test, when you have a neighboring color in the image. But he cannot definitely say about the “breakdown” of the PG; perhaps you just have dirty parking in the printer. Therefore, it is necessary to remove the PG and perform diagnostics using the method described above, and only then carry out or refuse washing.

- For pigment and water-based inks, it is most likely better to use different liquids, but there is still no recipe that would give 100% results.

- Don’t be lazy and replace the liquid in the PG every hour, driving it with a syringe under pressure, this will give a good result!

- If you found good remedy, write, I’ll try to make it, possibly modify it, and this will ultimately lead to the production of a liquid that will help in much larger cases.

And now the video itself.

One, Two, Three - bring your printer to life!

Preface

Even the most reliable equipment, from time to time, requires preventative maintenance and minor repairs to promptly eliminate small problems that would otherwise lead to undesirable consequences.

Thermal and piezo print heads inkjet printers periodically require preventive cleaning work. Droplets of ink remain on the fittings and nozzles of the printed elements and then dry out, dust and dirt are deposited from the air...

There are often cases when, out of ignorance, owners of inkjet printers use pigment dyes after water-soluble dyes, which is strictly prohibited and leads to defects in the printing devices. In all of the above cases, only one thing will help - washing the print head using special service fluids.

Among several types of service fluids for servicing cartridges and print heads of printers found on the Internet, fluids from the German company OCP attract the most attention. It seems like a trifle - a liquid is a liquid, it will perform its functions well and okay, but even here the Germans have thought through everything to the smallest detail.

The uniqueness of the product is that it is color-coded - out of 8 OCP service fluids, each special fluid has its own color and specific purpose.

So:

OCP service fluids. Purpose.

OCP RSL(Rinse Solution Liquid) or “OCP base fluid” is the most popular and widely used flushing fluid. Its composition is very close to the OCP ink base, with the addition of specially selected surfactants and alcohols necessary for the soaking and washing process. It is thanks to these features that ErSeElka, as it is affectionately called by servicemen, in most cases copes with the assigned tasks perfectly and therefore has become widespread in service centers(Fig.1)

Description: liquid is light yellow in color, with a characteristic odor, of medium aggressiveness. Has good cleaning properties.

Purpose:

— washing of internal surfaces ink cartridges;

— washing the absorbent material (absorber) of inkjet cartridges;

— flushing the print head channels;

— soaking the print head nozzle plate;

— washing the tray and the entire pump path of inkjet printers.

Features of operation: For a more effective process of cleaning the print head, the OCP RSL service fluid must be used heated to a temperature of 35⁰C - 50⁰C (the approximate temperature range is indicated, it is better to stick to the average or maximum value, since the service fluid cools down quite quickly). Heating can be done in a microwave oven (if the bottle contains 100 g, be sure to remove the packaging foil under the stopper!) for a few seconds at maximum power or in a water bath (a container with boiling water).

OSR CRS(Concentrate Rinse Solution). Liquid concentrate RSL 1:3 (Fig. 2)

Description: liquid of rich yellow color, with a characteristic odor, highly aggressive. Use only after dilution with OCP PIW (see description below). Proportions for obtaining standard RSL liquid: one part OCP CRS three parts OCP PIW.

Attention! Without diluting the concentrate, using it in its pure form is dangerous for all types of print heads and cartridges, since it is very aggressive and can dissolve plastic.

OCP CCF (CISS). Liquid for washing CISS (CISS cleaning Liquid)

Description: light blue liquid with a weak characteristic odor (Fig. 3)

Purpose: used as a flushing liquid for CISS systems (Continuous Ink Supply Systems) to remove ink residues. It is practically non-aggressive and has the ability to block corrosion. Recommended for use as a print head preservative during long periods of inactivity.

OCP EPS Cleaning Ink. Liquid for resuscitation of print heads of EPSON printers (Fig. 4)

Description: dark blue liquid with a weak characteristic odor.

Purpose: Direct filling into the cartridge and printing of the nozzle test on the printer is allowed. Only for EPSON! Not aggressive. Cleans worse than RSL.

OCP CFR(Cleaning Fluid Red). Liquid for removing ink traces (Fig. 5)

Description: light pink liquid with a characteristic odor.

Purpose: used as a detergent to remove traces of ink from the plastic surfaces of refillable cartridges or CSS.

Features of operation:

— Not used for soaking or washing the internal surfaces of cartridges and print heads.

OCP LCF III(Lexmark Cleaning Fluid). Service liquid for pigment (Fig. 6)

Description: transparent liquid with a pungent odor of ammonia, highly aggressive.

Purpose: used for soaking and washing the internal surfaces of cartridges and print heads from traces of pigment ink.

Features of operation: It is possible to use the liquid in two versions - with and without heating. More effective method soaking and washing - with heating the liquid to a temperature of at least 70⁰C. Heating can be done in a microwave oven (if the bottle contains 100 g, be sure to remove the packaging foil under the stopper!) for a few seconds at maximum power or in a water bath (a container with boiling water).

If the liquid is used at room temperature, it must be used during the soaking process for up to half an hour to an hour.

Regardless of the method of use, liquid must be removed from the cartridge or printhead after complete use, for which OCP RSL or OCP PIW are used.

The liquid is highly aggressive, and therefore it is not allowed to leave it in the print head for more than an hour!

OCP NRC(Nozzle Rocket Colorless). Flushing liquid with additional components (Fig. 7)

Description: transparent liquid with a sharp characteristic odor, increased aggressiveness.

Purpose: used for soaking and washing the internal surfaces of cartridges and print heads.

The composition contains additional components that destroy stable formations inside the cartridges. The liquid has

increased aggressiveness, which is why it is necessary to use it during the soaking process for up to half an hour.

Regardless of the method of use, the liquid must be removed from the cartridge or head after complete use, for which OCP RSL or OCP PIW are used.

OCP PIW(Pure Ink Water). Industrially purified water (Fig. 8)

Description: clear, odorless liquid.

Peculiarities: Special processing and purification systems make it possible to obtain an almost pure formula of H 2 O, the quality of purification is higher than distilled, and does not contain salts and metal ions.

Purpose:

— preparation of a standard solution of OCP RSL from OCP CRS;

— final washing of cartridges to remove residual washing liquids.

An excellent assistant when working with printing equipment will be washing liquid for inkjet printers. Epson printers, HP and Canon. A special composition is used to clean the print head from ink residues and increases its service life. Choose a model that matches the type of paint you use - for example, working with pigment will require a more active solution than photo ink. The liquid is presented in convenient containers with a sharp spout, so you do not have to use a medical syringe. You can pour the composition into the print head directly from the reservoir without pouring it into another container.

In what cases is it worth buying flushing fluid for inkjet printers?

- If the PU produces images with spots, stripes and other defects. When basic nozzle cleaning does not solve the problem, it is worth deep cleaning the print head using washing liquid.

- If you haven't used your inkjet printer for a long time, clogs of thickened ink may have formed in its system. The presented composition allows you to effectively and quickly get rid of them without harm to the device system.

- If you plan to use the new kind ink or paint from another manufacturer, it is worth buying washing fluid for inkjet printers and cartridges. It will allow you to avoid a situation where paints with different compositions enter into a chemical reaction, which can lead to an unexpected result.

Is it worth saving on flushing fluid for inkjet cartridges?

Experts do not recommend using water or homemade solutions instead of cleaning fluid. Water does not have active components that can dissolve dry ink particles in the printer system. It is difficult to predict how a homemade solution will interact with a printing device. At best, you will not get the desired result, and at worst, you will permanently damage the printer. Flushing liquid for jets Epson cartridges, HP and Canon from a trusted manufacturer is safe for printing equipment and does not void your printer warranty from the seller.

Typically, the prices of washing fluid for pigment inks and solutions for photo inks are the same. Choose the appropriate option when working with different paint compositions. We offer a composition that does not affect the speed and quality of printing, while effectively ridding the PU of ink residues in the system. For getting additional information about products, please contact our specialists.

OCP RSL

■ flush ■ yellow ■ designed for any inkjet printers

For washing the internal surfaces of cartridges (non-foam or after removing the foam), as well as print heads and components of CISS continuous supply systems (loops, capsules, cartridges, donor jars).

Used before changing ink to another manufacturer, before changing pigment ink to water-based (for undried pigment), as well as after using cleaning or soaking liquids (to neutralize their residues) before refilling with ink.

Peculiarities. Can be used at room temperature or heated. The washing process is accelerated if the liquid is preheated in a “water bath” to a temperature of 35C.

· Mode of application

Fill the volume to be washed with this liquid and let it sit for at least one hour, but not more than one day. Then drain the liquid from the volume being washed and fill the volume with ink. For a heavily contaminated volume, it is allowed to alternate filling with clean liquid, settling and draining several times, but the total time of exposure to this liquid should not exceed one day. Do not allow the liquid in the volume to be washed to dry out.

OCP CCF (OCP CISS)

■ flush ■ light blue ■ designed for EPSON inkjet printers

For washing the internal surfaces of cartridges (without foam or after removing the foam), as well as print heads, components of CISS continuous supply systems (loops, capsules, cartridges, donor jars).

Used before changing ink to another manufacturer, before changing pigment ink to water-based (for undried pigment), as well as after using cleaning or soaking liquids (to neutralize their residues) before refilling with ink. In addition, for preserving the print heads of inkjet printers before a long break in operation.

Method of use for preserving the print head

Fill functional empty cartridges completely with this liquid (it is recommended to use refillable cartridges with refill holes), install the cartridges in the printer and run the print head cleaning program once. (If before this the printer was standing with empty cartridges, then run the cleaning program three times in a row, turn off the printer with the button, leave it alone until the morning, and then turn on the printer and run the print head cleaning program once). This will fill the print heads with liquid. Then, without removing the cartridges from the printer, turn off the printer with the button and pack it in a sealed plastic bag for the storage period. This liquid can be left in the printheads for an extended period of time, but do not allow the liquid to dry out.

OCP ECI (OCP EPS)

■ cleaning ■ blue ■ designed for EPSON inkjet printers

For cleaning print heads from dried ink.

Peculiarities. Use at room temperature.

· Methods of application:

a) clean the heads with this liquid using the “Cleaning cartridge” method (described separately). The exposure time to this liquid should not exceed one day. Immediately after using this liquid, remove the cleaning cartridges from the printer, install ink cartridges into the printer and run the print head cleaning program twice in a row to replace the liquid in the heads with ink;

b) soak the outside of the head nozzles with this liquid using the “Sandwich” method (described separately). The exposure time to this liquid should not exceed one day. Immediately after soaking the heads, run the print head cleaning program at least once.

OCP NRC (OCP NRS)

For cleaning print heads from dried water-based and pigment inks.

Peculiarities. Use only at room temperature, without heating.

Method of application for heads removed from the printer

Soak the outside of the head nozzles with this liquid using the “Drop” method or the “Bath” method (described separately). The exposure time to this liquid should not exceed one hour.

OCP LCF III

■ soak-off ■ colorless ■ designed for any inkjet printers

For soaking and cleaning print heads from pigment, soaking heavily dried pigment ink in cartridges (non-sporen or after removing the foam) and in components of CISS continuous supply systems (loops, capsules, cartridges, donor jars).

Peculiarities. Can be used at room temperature or heated. The soaking process is significantly accelerated if the liquid is preheated in a “water bath” to a temperature of 60-70C.

Application methods for non-removable printer heads:

a) clean the heads with this liquid using the “Cleaning cartridge” method (described separately). The exposure time to this liquid should not exceed one hour. Immediately after using this soaking liquid, before refilling the heads with ink, remove the cleaning cartridges from the printer, install cleaning cartridges with another washing liquid into the printer and run the print head cleaning program twice in a row. Then remove the cleaning cartridges from the printer and install ink cartridges into the printer;

b) soak the outside of the head nozzles with this liquid using the “Sandwich” method (described separately). The exposure time to this liquid should not exceed one hour. Immediately after soaking the heads, run the print head cleaning program at least once.

b) for a print head combined with an ink tank into a monoblock, with very dry pigment ink. Lay oilcloth and several layers of newsprint on the table. Using a knife blade, carefully separate the top plastic cover from the candy bar using a rocking motion around the perimeter, completely remove the foam filler from it (do not throw it away!) and drain the remaining ink from the candy bar. Place the candy bar firmly on the table on a soft, dry cloth. Heat this soaking liquid in a “water bath” to 60C-70C and fill the internal volume of the monoblock completely with it. Allow to sit until the liquid cools to room temperature (but no more than an hour). Then drain this liquid, fill the internal volume of the monoblock flushing liquid and after 10-15 minutes drain it. Reinstall the foam filler into the monoblock and glue the top plastic cover of the monoblock into its original place. Fill the monoblock with ink, install it in the printer and run the print head cleaning program several times in a row.

OCP CFR

■ cleaning ■ red ■ designed for external plastic surfaces

For cleaning ink and dirt from the outer plastic surfaces of various products - cartridges, print heads, components of CISS continuous supply systems, printer cases, computers, etc.

Peculiarities. Do not pour inside cartridges or print heads.

· Mode of application

Soak a soft cloth in this liquid and wipe wet wipe surface requiring cleaning.

Service fluids InkTec, Ink-Mate (Korea)

InkTec MCS, Ink-Mate CS

■ cleaning ■ colorless ■ designed for any inkjet printers

For cleaning print heads from dried ink, including sublimation ink.

Peculiarities. Use at room temperature. Application methods for InkTec MCS and Ink-Mate CS fluids are the same

Method of application for non-removable printer heads

Soak the outside of the head nozzles with this liquid using the “Sandwich” method (described separately). A single exposure time to this liquid is not recommended for more than 10 minutes. Immediately after soaking the heads, run the print head cleaning program once and then run the nozzle test. If the nozzle test shows an unsatisfactory result, repeat the process of soaking the nozzles using the “Sandwich” method another 2-3 times for 10 minutes.

Methods of application for monobloc heads removed from the printer (integrated with the ink tank):

a) place the print head with nozzles under a slow stream of running hot water at a temperature of 40-50C to a depth of 1 cm for about 10 minutes. Then place a suitable container (for example, a plastic plate) on the table and place a dry napkin on the bottom of the container. Pour cleaning liquid into the container (up to 1 cm deep). Place the head with the nozzles in the liquid on a napkin. Be careful - the head contacts should not get wet! After 10 minutes, remove the head from the container and blot the nozzles with a dry cloth. Check - if liquid has leaked under the electrical cable of the head, then the cable must be completely dried before installing the head in the printer! Then install the head into the printer, run the print head cleaning program once and then test the nozzles. If the nozzle test shows an unsatisfactory result, put the nozzle head back into the cleaning liquid and repeat the entire process described 2-3 more times;

b) in the presence of a professional ultrasonic bath. Place a suitable container (for example, a plastic plate) on the table and place a dry napkin on the bottom of the container. Pour cleaning liquid into the container (up to 1 cm deep). Place the head with the nozzles in the liquid on a napkin. Be careful - the head contacts should not get wet! After 3 minutes, remove the head from the container. Then for 5 (five) seconds (no more, to avoid damage to the head!) immerse the head with nozzles in an ultrasonic bath filled with distilled water. Remove the head from the bath and blot the nozzles with a dry cloth. Check - if liquid has leaked under the electrical cable of the head, then the cable must be completely dried before installing the head in the printer! After this, install the head into the printer, run the print head cleaning program once and then test the nozzles. If the nozzle test shows an unsatisfactory result, again place the head with the nozzles in the cleaning liquid and repeat the entire described process 2-3 more times.

Service fluids InkMaster (England)

InkMaster Flushing

■ washable ■ colorless ■ designed for any inkjet printers

For final washing of the internal surfaces of cartridges (non-foam or after removing the foam), as well as print heads, components of CISS continuous supply systems (loops, capsules, refillable cartridges, donor jars).

Used before changing ink to another manufacturer, before changing pigment ink to water-based (for undried pigment), as well as after using cleaning or soaking liquids (to neutralize and wash out their residues) before refilling with ink. In addition, for preserving the print heads of any inkjet printers before a long break in operation.

Peculiarities. Use at room temperature.

Method of application for washing

Fill the volume to be washed with this liquid and let it sit for several hours. Then drain the liquid from the volume being washed and fill the volume with ink. For a heavily contaminated volume, it is possible to alternate several times between filling with clean liquid, settling and draining. This liquid can be left in the volume being washed for a long time, but do not allow the liquid to dry out.

Method of use for preserving the print head of the printer

Fill functional empty cartridges completely with this liquid (it is recommended to use refillable cartridges with refill holes), install the cartridges in the printer and run the print head cleaning program once. (If before this the printer was standing with empty cartridges, then run the cleaning program three times in a row, turn off the printer with the button, leave it alone until the morning, and then turn on the printer and run the print head cleaning program once). This will fill the print heads with liquid. Then, without removing the cartridges from the printer, turn off the printer with the button and pack it in a sealed plastic bag for the storage period. This liquid can be left in the printheads for an extended period of time, but do not allow the liquid to dry out.

InkMaster Recovery ("recovery")

■ cleaning ■ colorless ■ designed for any inkjet printers

For cleaning and restoring print heads from dried water-based and pigment inks.

Peculiarities. It is highly effective. Use only at room temperature, without heating.

Application methods for non-removable printer heads:

a) clean the heads with this liquid using the “Cleaning cartridge” method (described separately). The exposure time to this liquid should not exceed one hour. Immediately after using this cleaning liquid, before refilling the heads with ink, remove the cleaning cartridges from the printer, install cleaning cartridges with another washing liquid into the printer and run the print head cleaning program twice in a row. Then remove the cleaning cartridges from the printer and install ink cartridges into the printer;

b) soak the outside of the head nozzles with this liquid using the “Sandwich” method (described separately). The exposure time to this liquid should not exceed one hour. Immediately after soaking the heads, run the print head cleaning program at least once.

Application methods for removable printer heads:

a) soak the outside of the head nozzles with this liquid using the “Drop” method or the “Bath” method (described separately). The exposure time to this liquid should not exceed one hour;

b) for a print head combined with an ink tank into a monoblock, with very dry ink. Lay oilcloth and several layers of newsprint on the table. Using a knife blade, carefully separate the top plastic cover from the candy bar using a rocking motion around the perimeter, completely remove the foam filler from it (do not throw it away!) and drain the remaining ink from the candy bar. Place the candy bar firmly on the table on a soft, dry cloth. Fill the internal volume of the monoblock completely with this liquid. Let sit for one hour (but no more than an hour). Then drain this liquid, fill the internal volume of the monoblock with flushing liquid and drain it after 10-15 minutes. Reinstall the foam filler into the monoblock and glue the top plastic cover of the monoblock into its original place. Fill the monoblock with ink, install it in the printer and run the print head cleaning program several times in a row.

Methods of exposure to service fluids

Printhead cleaning method "Cleaning cartridge"

Fill spare functional empty cartridges completely with the required service fluid. (If possible, it is recommended to use refillable cartridges - they have ready-made refill holes with plugs). Install the resulting cleaning cartridges into the printer. Run the printhead cleaning program twice in a row. In this case, the liquid from the cartridges will fill the print heads of the printer. Then, during the required time of exposure of the liquid to the heads, print some texts, images onto plain paper and periodically run a nozzle test. (If the liquid is colorless, you can pre-tint it with one drop of colored ink and see the print quality of the heads on the paper). The time of exposure of the liquid to the heads must be controlled - it is different for different liquids.

(Be careful - when servicing the heads, do not remove the cartridges from the heads for more than a minute to avoid airing the head channels. A sign of airing the head channels - there is ink in the cartridges, but when printing, the ink does not pass through all the nozzles onto the paper, and starting up does not help cleaning program. If you turn off the printer and leave it alone until the morning, the air will come out of the heads on its own).

After using cleaning cartridges with cleaning or soaking liquid, if the cartridges contain metal elements inside (for example, a strainer, an outlet valve spring), then you need to drain the remaining liquid from the cartridges and then rinse the volume of the cartridges with washing liquid to avoid metal corrosion. It is impossible to drain the remaining liquid from cleaning cartridges with foam filling. Therefore, if they contain metal elements, then the life of such cleaning cartridges will be limited.

"Sandwich" print head nozzle cleaning method

Prepare dry, thick paper napkins or toilet paper - such that the lint does not separate from them, and so that when wetted the paper does not fall apart into shreds. Prepare a piece of smooth plastic film (for example, cut from a thick bag or from the side of a drinks bottle) slightly larger than the “drop guard” in the print head parking area of the printer. Turn on the printer. Move the print heads to the cartridge replacement position, and then unplug the printer's power cord from the outlet. (In this case, the printer heads must remain in the cartridge replacement position. Do not remove the cartridges). If you use CISS, temporarily plug all the plugs on the CISS donor jars. Carefully spread the prepared piece of film over the surface of the mouth guard. Place a piece of prepared paper of approximately the same size on top of it and evenly saturate the paper with the required service fluid using a bottle with a long spout or a syringe. Carefully push the print heads into the extreme position of the parking space by hand, making sure that the sandwich of film and paper placed on the “drip” does not slide to the side. In the extreme position, the sandwich will be pressed against the nozzles of the heads. Leave the heads alone for a while. Since the paper with the liquid gradually dries out, during the total exposure time the heads can be extended and retracted several times while changing the paper to a new one, newly soaked in liquid. The time of exposure of the liquid to the heads must be controlled - it is different for different liquids. Immediately after the end of exposure to the cleaning or soaking liquid, you need to pull out the heads, replace the sandwich paper with a new one, soaked in a new washing liquid (to neutralize the remnants of more aggressive liquids), push the heads back into the parking space and leave the heads pressed against the sandwich for another 10-15 minutes. After this, pull out the heads, remove the sandwich from the “drop guard” and push the heads back into the parking space.

Method of cleaning print head nozzles "Drop"

Cover the table with oilcloth and several sheets of newsprint on top of the oilcloth. Remove the print head from the printer and place it on the table upside down so that the nozzle plate is on top and parallel to the table surface. Carefully apply 2-3 drops of the required service fluid onto the nozzle plate. Drops will slowly seep into the nozzles. Be careful - do not allow liquid to flow onto the electrical cable and head contacts! During the required exposure time, repeatedly apply drops of liquid to the nozzle plate. The time of exposure of the liquid to the head must be controlled - it is different for different liquids. Immediately after using the cleaning or soaking liquid, blot the head nozzles with a cloth moistened with the washing liquid. Check - if any liquid has leaked under the electrical cable of the head, then the cable must be completely dried before installing the head in the printer! Install the ink head into the printer and run the nozzle test at least three times in a row, as well as the print head cleaning program once. (Because the head has been upside down for some time, the ink may have leaked from the head and it may not print right away. In this case, you need to leave it alone in the printer for one to two hours, and then run the printhead cleaning program several times.)

"Bath" method for cleaning print head nozzles

Place a suitable container (for example, a plastic plate) inside a plastic bag on the table. Place a dry cloth at the bottom of the container. Pour the required service fluid into the container (3-5 mm deep). Remove the print head from the printer and immerse the nozzles in the liquid on a napkin. Be careful - the head contacts should not get wet! Seal the top of the bag tightly to reduce liquid evaporation. After the required exposure time has elapsed, remove the head from the container with liquid. The time of exposure of the liquid to the head must be controlled - it is different for different liquids. Immediately after using the cleaning or soaking liquid, blot the head nozzles with a clean cloth moistened with the cleaning liquid. Check - if any liquid has leaked under the electrical cable of the head, then the cable must be completely dried before installing the head in the printer! Install the ink head into the printer and run the nozzle test at least three times in a row, as well as the print head cleaning program once.

Order 343 mail. Order by Russian post. Consequences of failure to appear in court when summoned

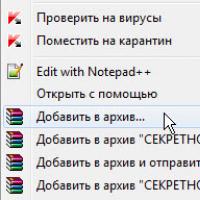

Order 343 mail. Order by Russian post. Consequences of failure to appear in court when summoned How to put a password on a folder on a Windows computer without and with programs

How to put a password on a folder on a Windows computer without and with programs Pluton – Free Bootstrap HTML5 One Page Template

Pluton – Free Bootstrap HTML5 One Page Template History of ZX Spectrum: Myths and reality New Spectrum

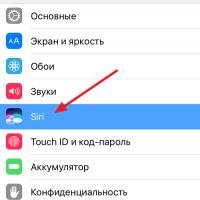

History of ZX Spectrum: Myths and reality New Spectrum Voice assistant Siri from Apple Siri functions on iPhone 6s

Voice assistant Siri from Apple Siri functions on iPhone 6s How to roll back to a previous version of iOS?

How to roll back to a previous version of iOS? Unlock iPad in four days

Unlock iPad in four days